Welded Wire Mesh

A reliable and versatile solution for construction, fencing, and industrial reinforcement.

About Welded Wire Mesh

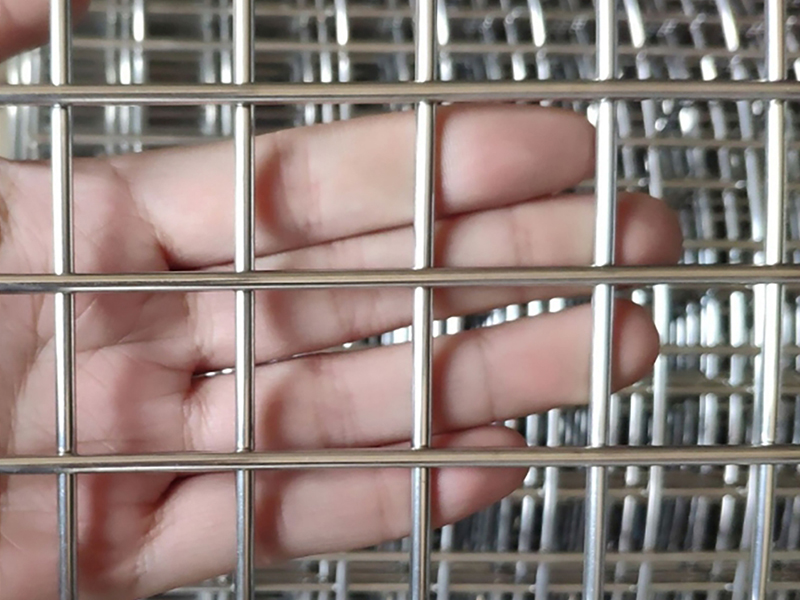

Welded wire mesh is a grid structure formed by welding steel wires at each intersection.

Compared with woven mesh, welded mesh has a stronger bond and remains firm even under pressure.

It is widely used in reinforced concrete, safety fencing, cages, partitions, and industrial supports.

The mesh can be supplied in rolls or sheets, made from low carbon steel, galvanized steel, or stainless steel.

Depending on the surface treatment, welded wire mesh can achieve excellent corrosion resistance, smooth surface,

and long service life. This makes it an ideal choice for applications where strength, durability, and stability are required.

Key Features of Welded Wire Mesh

Strong Welding

Each intersection is welded firmly with advanced automatic welding machines.

The mesh will not loosen or deform easily, even after long-term use.

Corrosion Resistance

Available in galvanized, PVC-coated, and stainless steel materials,

ensuring long service life in harsh outdoor and industrial environments.

Customizable Options

Mesh size, wire diameter, sheet size, and surface treatment can all be customized

according to project requirements, offering flexibility for different industries.

Wide Applications

From fencing and barriers to concrete reinforcement and industrial cages,

welded mesh is a versatile solution trusted by engineers and contractors worldwide.

Welded Wire Mesh Specifications

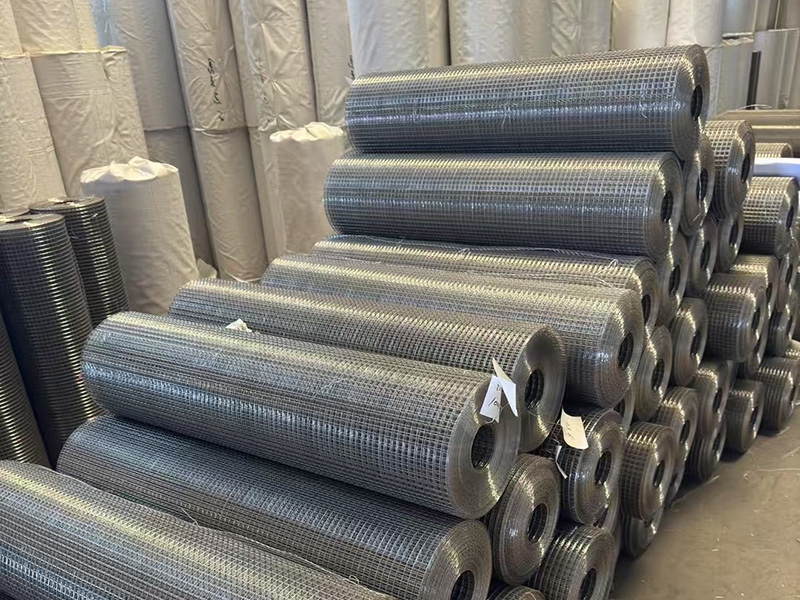

Our welded wire mesh can be supplied in both rolls and flat panels.

The mesh is available in a wide range of wire diameters and mesh openings,

making it suitable for light fencing as well as heavy-duty reinforcement applications.

Standard materials include low carbon steel wire, hot-dip galvanized wire,

electro-galvanized wire, and stainless steel wire. Surface treatments such as

galvanization and PVC-coating can be applied to enhance corrosion resistance and extend service life.

Below you can download the detailed specifications sheet, which includes wire diameter,

mesh opening size, sheet dimensions, and surface finish options.

Click below to view or download the detailed technical specifications of our welded wire mesh.

Download / View Full Specifications (PDF)

Applications of Welded Wire Mesh

Welded wire mesh is widely recognized for its strength and versatility.

It is trusted in multiple industries, providing reliable support and protection.

Here are some of the main application areas:

Construction Reinforcement

Used in concrete slabs, walls, columns, and foundations, welded mesh provides stability and prevents cracking.

Fencing & Security Barriers

Ideal for garden fences, highway barriers, and perimeter security.

Strong, durable, and resistant to deformation.

Industrial & Agricultural Use

Widely applied in storage racks, cages, animal husbandry, and greenhouse supports.

Infrastructure Projects

Essential in tunnels, airports, bridges, and highways for reinforcement and safety.

Production Process of Welded Wire Mesh

Our welded wire mesh is produced through a standardized process.

From raw material to final packaging, every step is carefully controlled

to guarantee strong welding points, accurate dimensions, and stable quality.

Wire Drawing

High-quality steel rods are drawn into wires of required diameters, ensuring smooth surfaces and uniform strength.

Straightening & Cutting

The wires are straightened and cut precisely to standard lengths, ready for welding.

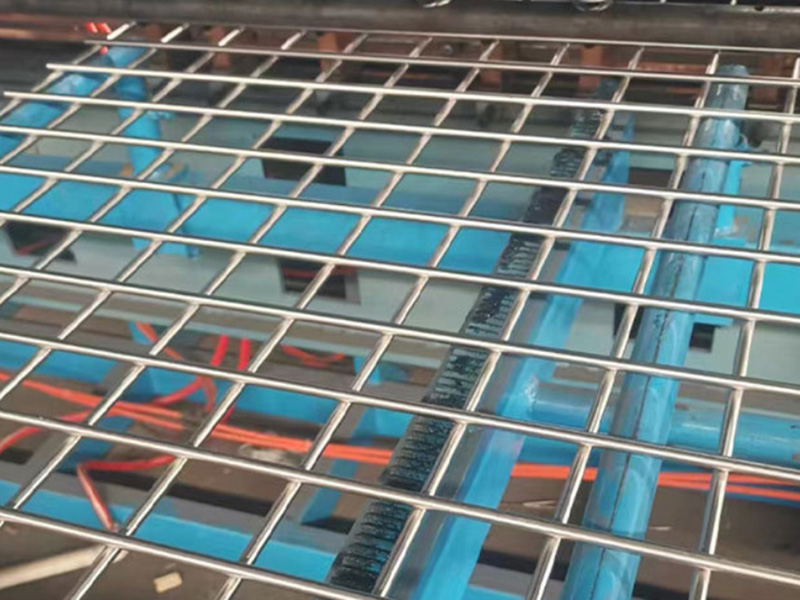

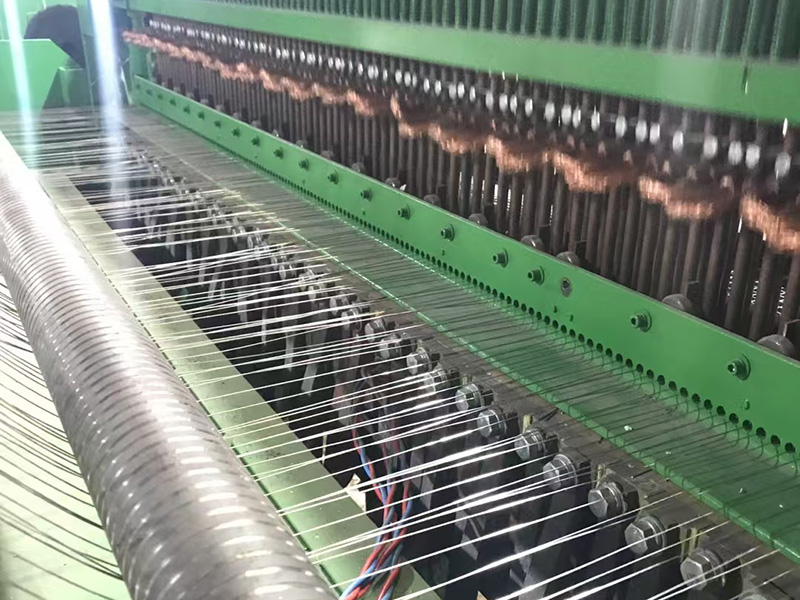

Automatic Welding

Intersecting wires are welded firmly at right angles by advanced welding machines, ensuring stable mesh structure.

Inspection

Each mesh panel or roll is carefully inspected to ensure uniform mesh size, strong welding points, and accurate dimensions.

Inspection & Packaging

Finished welded wire mesh is packed in rolls or flat panels, ready for shipment and easy handling.

Quality Assurance

At Maidong Metal Mesh, quality is our top priority.

We strictly control every stage of production to ensure that our welded wire mesh meets international standards

and exceeds customer expectations.

Strict Raw Material Control

Only high-quality steel wires are selected to ensure uniform strength and durability.Precision Welding Technology

Automatic welding machines guarantee firm welding points and stable mesh structure.Comprehensive Inspection

Each batch is tested for mesh size, welding strength, and dimensional accuracy before packing.Reliable Packaging & Delivery

Mesh rolls and panels are carefully packed to avoid damage during transportation.

Our commitment to quality ensures that every roll and panel of welded wire mesh is built to last,

providing reliable performance in construction, fencing, and industrial applications.

Start Your Project with Welded Wire Mesh

We guarantee a quick response within 12 hours and a competitive quote.

📧 Email: sales@md-wiremesh.com

📱 WhatsApp: +86-15132829996

🌐 Website: www.mdwiremesh.com

🔗more info : linktr.ee/zcc5886