Woven Wire Mesh

Precision Woven Wire Mesh for Industrial Filtration Applications

Woven Mesh with Different Weave Types for Various Industrial Filtration

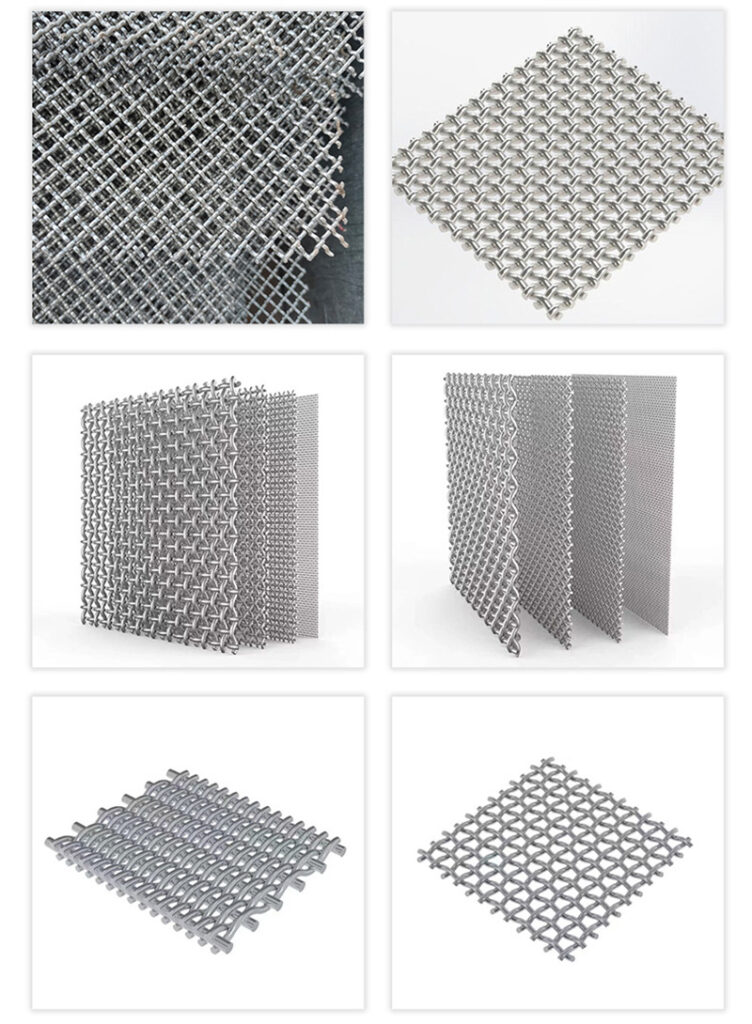

Woven mesh is constructed from high quality stainless steel wires, nickel wires, copper wires, brass wires, Monel wires, Hastelloy wires and other metal wires using advanced weaving technology. It features high temperature resistance, corrosion resistance, high tensile strength and great durability. In addition, its precise aperture size ensures a stable filter rating.

As one of the main filter materials, woven mesh can be fabricated into round, belt, cylinder, pleated, and other shape filter elements. It is widely used in separation and filtration of petroleum, chemical, pharmaceutical, food and other industries.

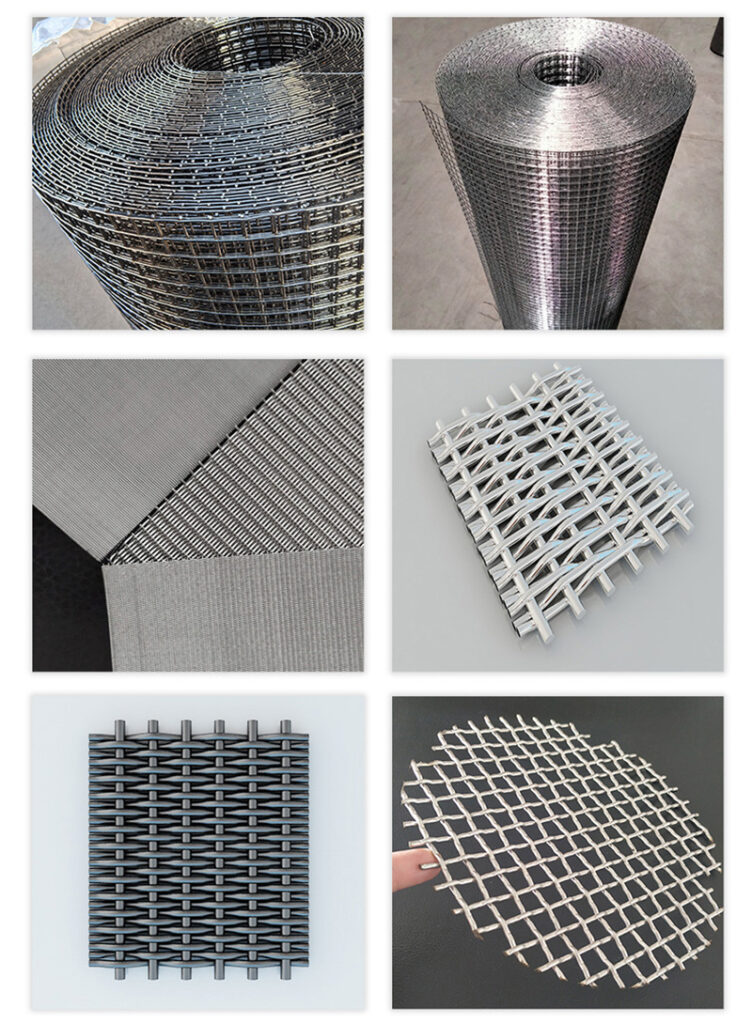

Woven Wire Mesh Categories

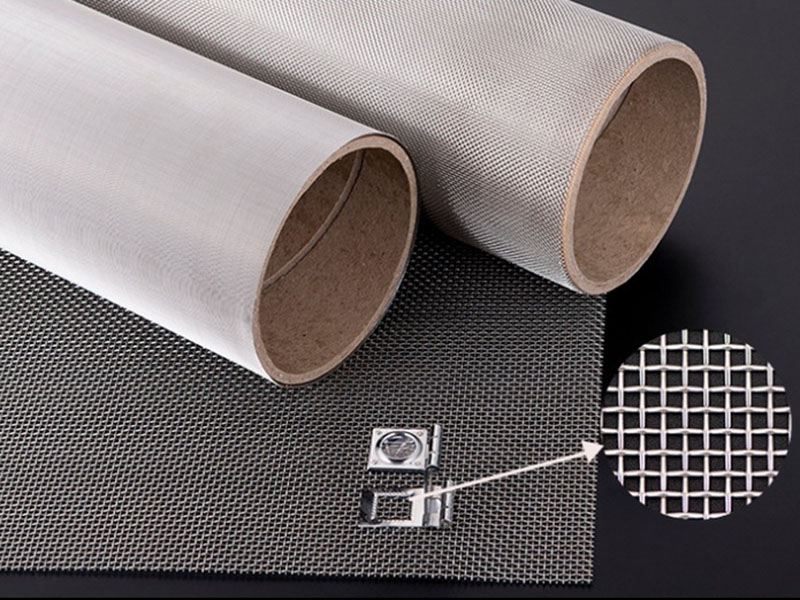

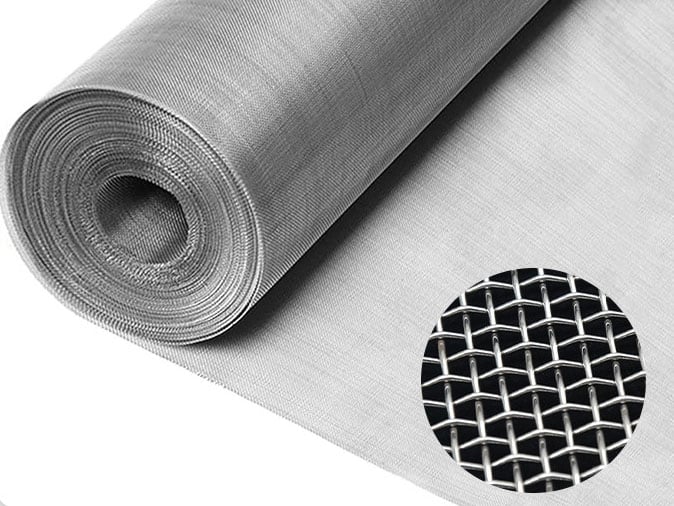

Precision Stainless Steel Wire Mesh

304/316 stainless steel woven mesh for industrial filtration, screening, and protection applications.

Learn More

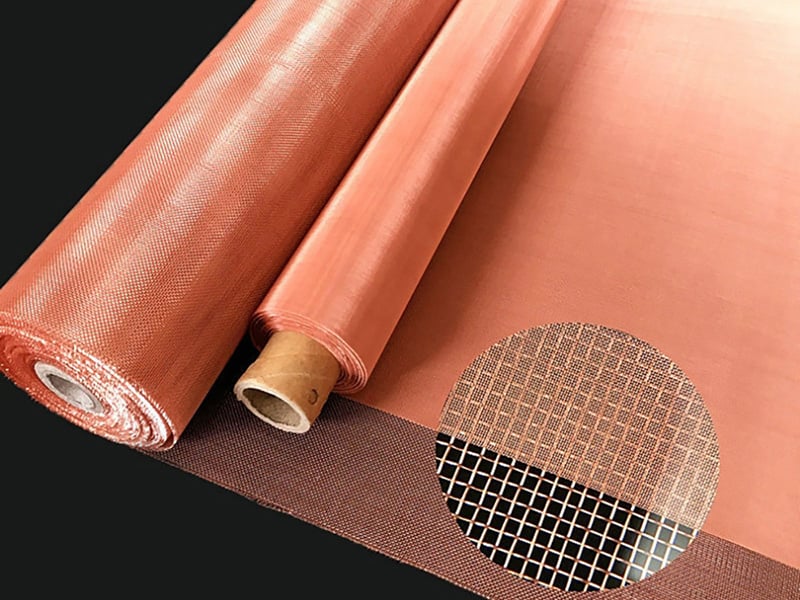

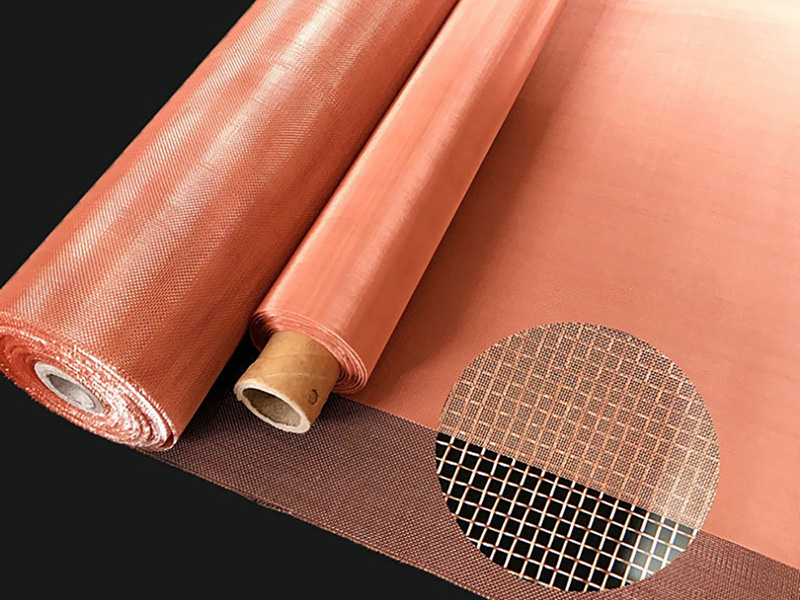

Copper Wire Mesh (EMI Shielding)

High-conductivity copper mesh for EMI/RFI shielding, filtration, and architectural applications.

Learn More

Dutch Weave Mesh (Fine Filtration)

Precision Dutch weave mesh designed for fine filtration of liquids, chemicals, and viscous materials.

Learn More

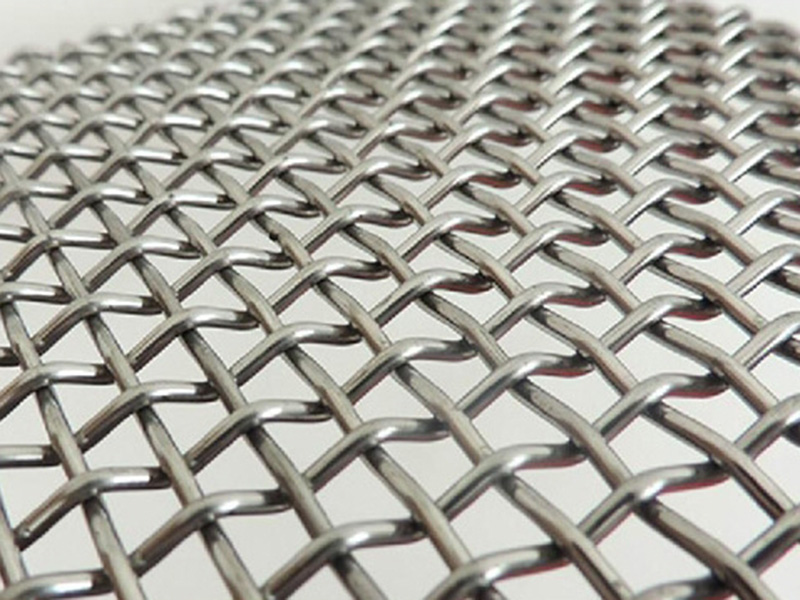

Crimped Wire Mesh

Durable crimped wire mesh for mining screens, fencing, reinforcement, and heavy-duty separation.

Learn More

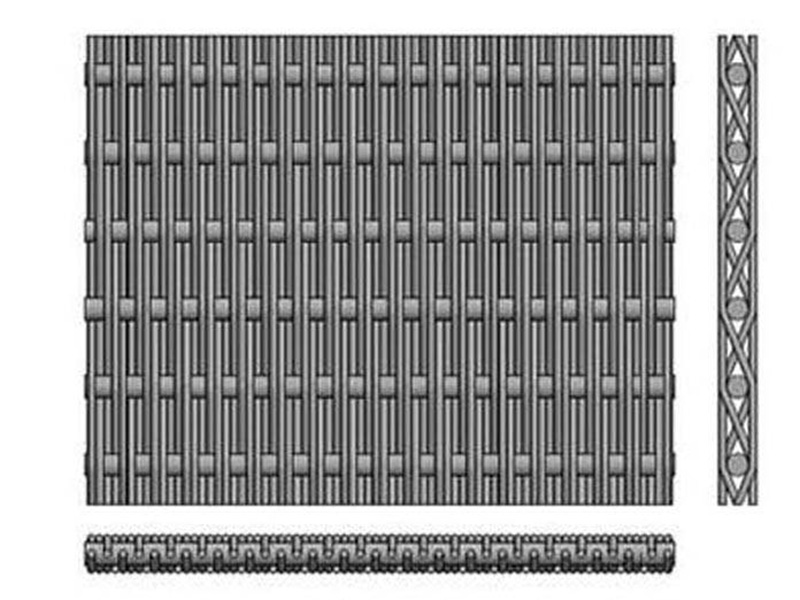

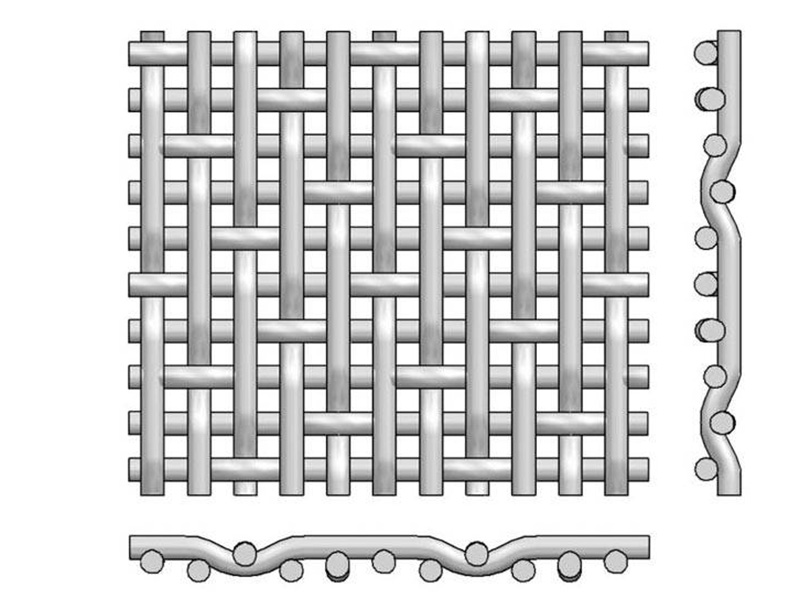

Weave Type

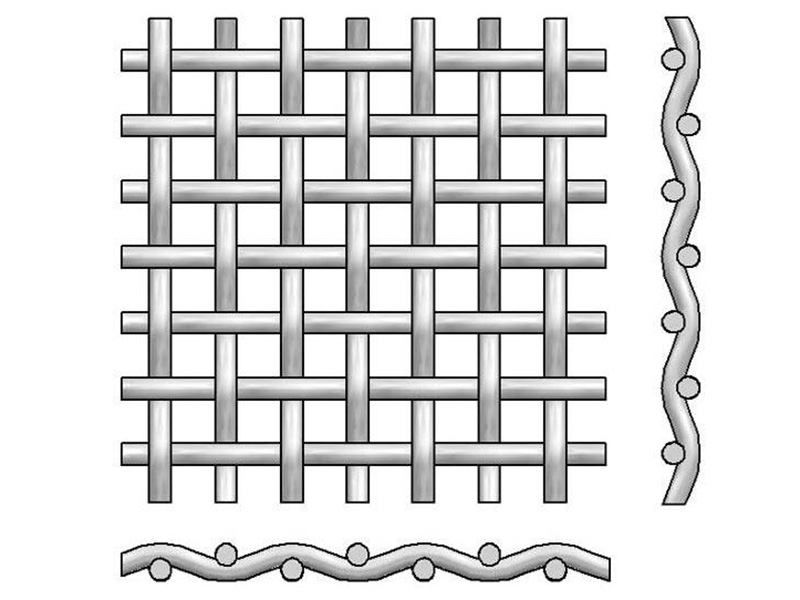

Plain Weave

The most common weaving, wires pass alternately over and under for uniform openings.

Twill Weave

Each wire passes alternately over two and under two for tighter mesh and higher strength.

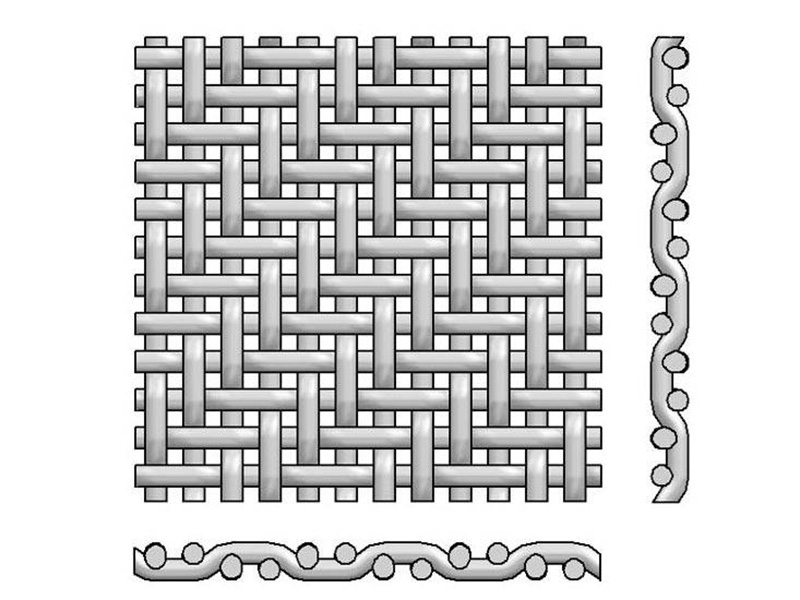

Plain Dutch Weave

Warp wires are thicker and denser, weft wires are finer, giving high filtration precision.

Twill Dutch Weave

Similar to plain Dutch but with a twill pattern — tighter and smoother surface.

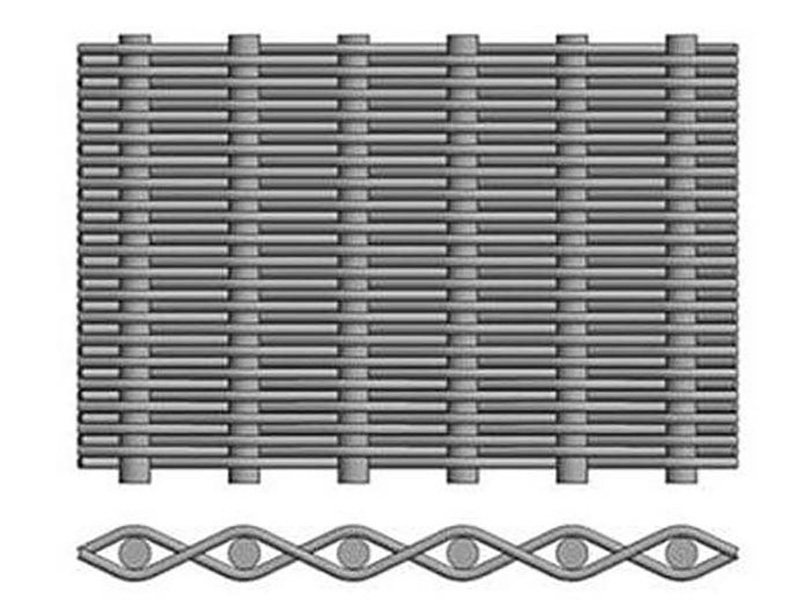

Reverse Dutch Weave

Warp wires are finer, weft wires are thicker, allowing high pressure and easy backwash.

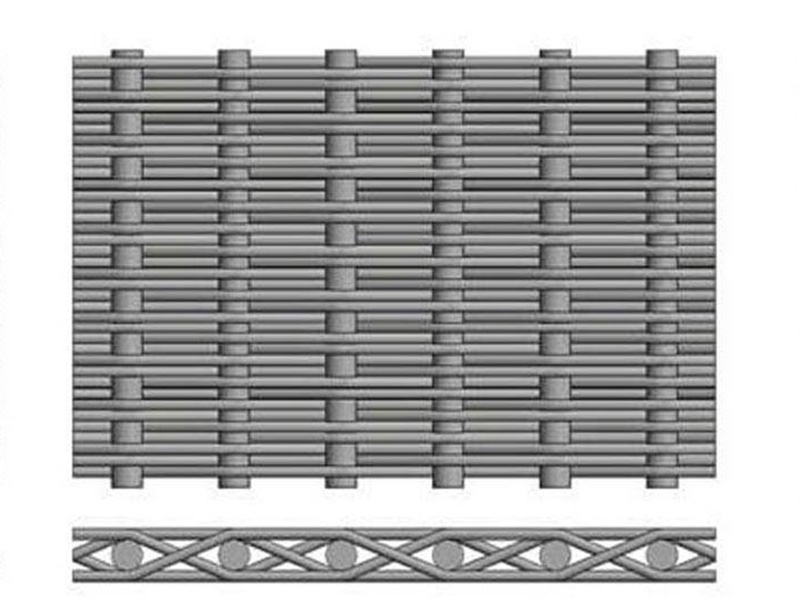

5-Heddle Weave

Flat and smooth surface with large open area, ideal for process belts and filtration.

Why Choose Our Woven Wire Mesh

Designed for industrial performance, our woven wire mesh offers multiple advantages that ensure reliability and cost-effectiveness in every application.

Superior Corrosion Resistance

Made from premium 304 and 316 stainless steel, our mesh withstands harsh chemical and marine environments without rusting or degrading.

Precision Engineering

Manufactured to ASTM E2016 standards with accurate wire diameter and mesh openings, ensuring consistent filtration performance.

Custom Solutions

Available in multiple weave styles and customizable sizes, we deliver tailored mesh products to meet unique industrial requirements.

High Strength & Stability

Strong structure with excellent dimensional stability under tension and vibration.

Clean & Hygienic

Smooth surface for easy cleaning; ideal for food, pharma, and precision filtration.

Temperature & Wear Resistance

Reliable under elevated temperatures and frequent operation for long service life.

Manufacturing Process

From premium raw materials to precise woven mesh, every step is strictly controlled to ensure quality and consistency.

Wire Drawing

Wires are drawn to precise diameters, ensuring uniform thickness and strength.

Annealing

Wires are heat-treated to remove stress and improve flexibility for weaving.

Weaving

Advanced looms weave the wires into plain, twill, or Dutch mesh under strict tolerance control.

Inspection

Mesh opening, wire diameter, and tensile strength are thoroughly inspected to meet standards.

Packaging

Finished meshes are securely packed in rolls or sheets for safe delivery worldwide.

Applications

Discover where our metal wire mesh products are making a difference.

Water Treatment

Used in wastewater and process water purification, ensuring clean and reliable filtration.

Learn More

Chemical Industry

Used in chemical production lines for liquid and gas filtration, protecting process equipment and ensuring product purity.

Learn More

Food & Beverage

Ensures hygiene and precision filtration in brewing, dairy, and beverage processing for food-grade safety.

Learn More

Oil & Gas Industry

Used in drilling mud filtration, gas–liquid separation, and oil refining to protect pipelines and improve production efficiency.

Learn More

Pharmaceutical Industry

Used in sterile filtration, air purification, and liquid-solid separation to meet strict sanitary standards.

Learn More

Power & Energy Industry

Used in turbine lubrication systems, cooling water filtration, and environmental protection equipment to ensure safe and stable operation.

Learn More

Hydraulic & Metallurgy Industry

Provides efficient filtration for hydraulic oil, rolling mills, and smelting processes, preventing contamination and extending equipment life.

Learn More

Plastics & Chemical Fiber Industry

Applied in polymer filtration, extrusion, and fiber spinning processes to ensure material purity and uniform flow.

Learn More

Woven Wire Mesh – Standard Specifications & Custom Options"

For quick matching, please provide:

material, mesh or aperture, wire diameter, width, roll length, and application medium/temperature.

We will reply within 2 hours with a recommended spec and quote.

📄 Download/View Online PDF Specs(Stainless Steel Woven Mesh)

| Mesh Count mesh/inch |

Wire Diameter | Mesh Opening | Open Area % |

Max. Width mm |

Theoretical Weight kg/m² |

||

|---|---|---|---|---|---|---|---|

| inch | mm | inch | mm | ||||

| 1 × 1 | 0.08 | 2.03 | 0.92 | 23.37 | 84.6 | 2000 | 2.06 |

| 2 × 2 | 0.063 | 1.6 | 0.437 | 11.1 | 76.4 | 2000 | 2.56 |

| 3 × 3 | 0.054 | 1.37 | 0.279 | 7.09 | 70.1 | 2000 | 2.82 |

| 4 × 4 | 0.063 | 1.6 | 0.187 | 4.75 | 56 | 2000 | 5.12 |

| 4 × 4 | 0.047 | 1.19 | 0.203 | 5.16 | 65.9 | 2000 | 2.83 |

| 5 × 5 | 0.041 | 1.04 | 0.159 | 4.04 | 63.2 | 2000 | 2.7 |

| 6 × 6 | 0.035 | 0.89 | 0.132 | 3.35 | 62.7 | 2000 | 2.38 |

| 8 × 8 | 0.028 | 0.71 | 0.097 | 2.46 | 60.2 | 2000 | 2.02 |

| 10 × 10 | 0.025 | 0.64 | 0.075 | 1.91 | 56.3 | 2000 | 2.05 |

| 10 × 10 | 0.02 | 0.51 | 0.08 | 2.03 | 64 | 2000 | 1.3 |

| 12 × 12 | 0.023 | 0.584 | 0.06 | 1.52 | 51.8 | 2000 | 2.05 |

| 12 × 12 | 0.02 | 0.508 | 0.063 | 1.6 | 57.2 | 2000 | 1.55 |

| 14 × 14 | 0.023 | 0.584 | 0.048 | 1.22 | 45.2 | 2000 | 2.39 |

| 14 × 14 | 0.02 | 0.508 | 0.051 | 1.3 | 51 | 2000 | 1.81 |

| 16 × 16 | 0.018 | 0.457 | 0.0445 | 1.13 | 50.7 | 2000 | 1.67 |

| 18 × 18 | 0.017 | 0.432 | 0.0386 | 0.98 | 48.3 | 2000 | 1.68 |

| 20 × 20 | 0.02 | 0.508 | 0.03 | 0.76 | 36 | 2000 | 2.58 |

| 20 × 20 | 0.016 | 0.406 | 0.034 | 0.86 | 46.2 | 2000 | 1.65 |

| 24 × 24 | 0.014 | 0.356 | 0.0277 | 0.7 | 44.2 | 2000 | 1.52 |

| 30 × 30 | 0.013 | 0.33 | 0.0203 | 0.52 | 37.1 | 2000 | 1.63 |

| 30 × 30 | 0.012 | 0.305 | 0.0213 | 0.54 | 40.8 | 2000 | 1.4 |

| 30 × 30 | 0.009 | 0.229 | 0.0243 | 0.62 | 53.1 | 2000 | 0.79 |

| 35 × 35 | 0.011 | 0.279 | 0.0176 | 0.45 | 37.9 | 2000 | 1.36 |

| 40 × 40 | 0.01 | 0.254 | 0.015 | 0.38 | 36 | 2000 | 1.29 |

| 50 × 50 | 0.009 | 0.229 | 0.011 | 0.28 | 30.3 | 2000 | 1.31 |

| 50 × 50 | 0.008 | 0.203 | 0.012 | 0.31 | 36 | 2000 | 1.03 |

| 60 × 60 | 0.0075 | 0.191 | 0.0092 | 0.23 | 30.5 | 2000 | 1.09 |

| 60 × 60 | 0.007 | 0.178 | 0.0097 | 0.25 | 33.9 | 2000 | 0.95 |

| 70 × 70 | 0.0065 | 0.165 | 0.0078 | 0.2 | 29.8 | 2000 | 0.95 |

| 80 × 80 | 0.0065 | 0.165 | 0.006 | 0.15 | 23 | 2000 | 1.09 |

| 80 × 80 | 0.0055 | 0.14 | 0.007 | 0.18 | 31.4 | 2000 | 0.78 |

| 90 × 90 | 0.005 | 0.127 | 0.0061 | 0.16 | 30.1 | 2000 | 0.73 |

| 100 × 100 | 0.0045 | 0.114 | 0.0055 | 0.14 | 30.3 | 2000 | 0.65 |

| 100 × 100 | 0.004 | 0.102 | 0.006 | 0.15 | 36 | 2000 | 0.52 |

| 100 × 100 | 0.0035 | 0.089 | 0.0065 | 0.17 | 42.3 | 2000 | 0.4 |

| 110 × 110 | 0.004 | 0.1016 | 0.0051 | 0.1295 | 30.7 | 2000 | 0.57 |

| 120 × 120 | 0.0037 | 0.094 | 0.0064 | 0.1168 | 30.7 | 2000 | 0.53 |

| 150 × 150 | 0.0026 | 0.066 | 0.0041 | 0.1041 | 37.4 | 2000 | 0.33 |

| 160 × 160 | 0.0025 | 0.0635 | 0.0038 | 0.0965 | 36.4 | 2000 | 0.32 |

| 180 × 180 | 0.0023 | 0.0584 | 0.0033 | 0.0838 | 34.7 | 2000 | 0.31 |

| 200 × 200 | 0.0021 | 0.0533 | 0.0029 | 0.0737 | 33.6 | 2000 | 0.28 |

| 250 × 250 | 0.0016 | 0.0406 | 0.0024 | 0.061 | 36 | 2000 | 0.21 |

| 270 × 270 | 0.0016 | 0.0406 | 0.0021 | 0.0533 | 32.2 | 2000 | 0.22 |

| 300 × 300 | 0.0051 | 0.0381 | 0.0018 | 0.0457 | 29.7 | 2000 | 0.22 |

| 325 × 325 | 0.0014 | 0.0356 | 0.0017 | 0.0432 | 30 | 2000 | 0.21 |

| 400 × 400 | 0.001 | 0.0254 | 0.0015 | 0.37 | 36 | 2000 | 0.13 |

| 500 × 500 | 0.001 | 0.0254 | 0.001 | 0.0254 | 25 | 2000 | 0.16 |

| 635 × 635 | 0.0008 | 0.0203 | 0.0008 | 0.0203 | 25 | 2000 | 0.13 |

📄 Download/View Online PDF Specs(Dutch Weave Wire Mesh)

| Mesh Count | Wire Diameter | Wire Diameter.1 | Filter Rating | Weight |

|---|---|---|---|---|

| Warp/Inch × Weft/Inch | inch | mm | μm | kg/m2 |

| 8 × 85 | 0.0140 × 0.01260 | 0.355 × 0.320 | 318–340 | 2.43 |

| 10 × 70 | 0.0240 × 0.01400 | 0.600 × 0.350 | 300–325 | 3.04 |

| 12 × 64 | 0.0230 × 0.01650 | 0.580 × 0.400 | 295–305 | 3.64 |

| 14 × 88 | 0.0190 × 0.01200 | 0.500 × 0.330 | 195–205 | 3.15 |

| 20 × 150 | 0.0098 × 0.00700 | 0.248 × 0.177 | 155–165 | 1.48 |

| 24 × 110 | 0.0150 × 0.01000 | 0.355 × 0.250 | 145–155 | 2.7 |

| 24 × 120 | 0.0130 × 0.00900 | 0.330 × 0.230 | 115–125 | 2.24 |

| 30 × 150 | 0.0090 × 0.00700 | 0.230 × 0.180 | 95–105 | 1.6 |

| 40 × 200 | 0.0070 × 0.00550 | 0.180 × 0.140 | 75–85 | 1.3 |

| 50 × 250 | 0.0055 × 0.00450 | 0.140 × 0.114 | 55–65 | 1 |

| 60 × 300 | 0.0055 × 0.00350 | 0.140 × 0.090 | 36–40 | 0.77 |

| 70 × 400 | 0.0047 × 0.00256 | 0.120 × 0.065 | 36–40 | 0.67 |

| 80 × 300 | 0.0049 × 0.00350 | 0.125 × 0.090 | 38–42 | 0.98 |

| 80 × 400 | 0.0049 × 0.00280 | 0.125 × 0.071 | 38–42 | 0.81 |

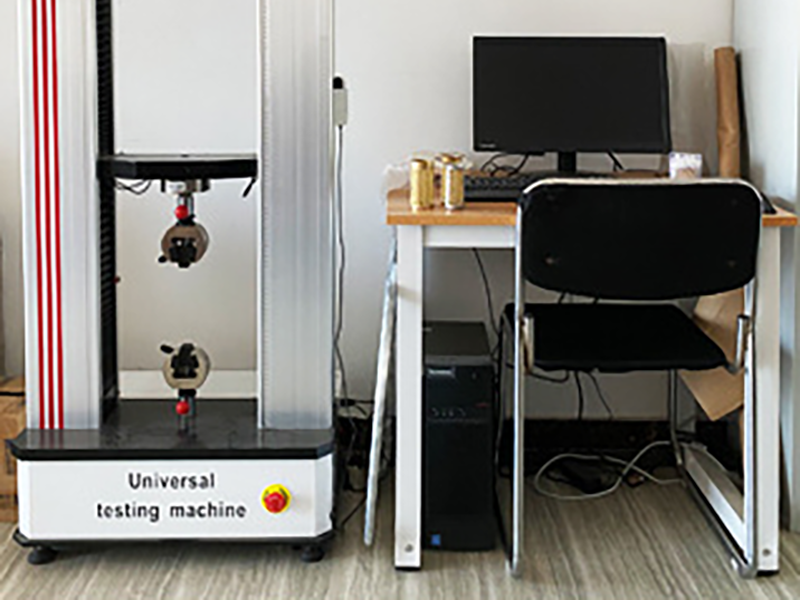

Quality & Inspection – Ensuring Top-Grade Stainless Steel Mesh

Every stainless steel mesh product undergoes strict quality control, from raw material selection to final inspection. We ensure consistent wire diameter, mesh count, tensile strength, and corrosion resistance for reliable performance in every application.

Raw Material Testing

Inspection of wire composition and tensile strength to ensure compliance with ASTM/ISO standards.

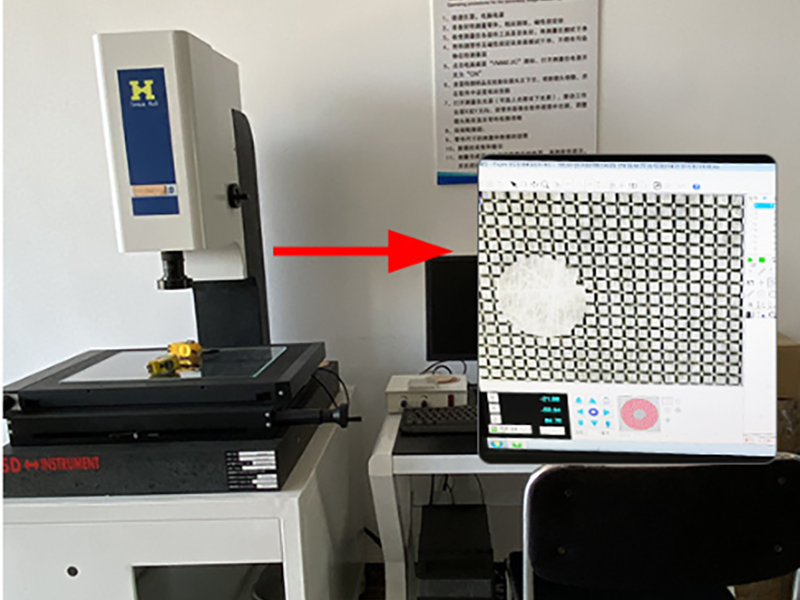

Precision Weaving & Measurement

Accurate mesh count and aperture size checked with high-precision measuring tools.

Final Inspection & Packaging

Surface finish, flatness, and roll length verified before moisture-proof packaging.

Our wire mesh products are manufactured under a strict quality assurance system, ensuring consistent performance in the most demanding environments. From raw material selection to final inspection, every step is closely monitored to meet ASTM and ISO standards. We guarantee precise mesh count, uniform wire diameter, high tensile strength, and superior corrosion resistance.

100% inspection of raw materials before production.

Mesh count and aperture size measured with high-precision tools.

Tensile strength and corrosion resistance tested in accordance with ASTM/ISO.

Surface flatness and roll length checked before packaging.

Comprehensive quality reports available upon request.

Quality Assurance

Our woven wire mesh products are manufactured under a strict quality control system to ensure precision and reliability. Each batch is inspected for wire diameter, mesh opening accuracy, weaving consistency, surface condition, and packaging safety before shipment.

Packaging & Delivery – Safe, Secure & On Time

Our wire mesh products are packed using moisture-proof wrapping, reinforced with wooden cases or pallets to prevent damage during transport. We cooperate with reliable logistics partners to ensure safe and timely delivery worldwide, whether by sea, air, or express.

Moisture-Proof Wrapping

Each roll is wrapped with plastic film or moisture-proof paper to avoid rust and contamination.

Reinforced Wooden Cases / Pallets

For bulk orders, rolls are secured in fumigated wooden cases or strapped on pallets for easier handling and stacking.

Custom Labels & Marking

Product specifications, batch numbers, and customer logos can be applied upon request.

Delivery Options

Sea Freight – Full Container Load (FCL) or Less-than-Container Load (LCL) shipments, suitable for bulk orders.

Air Freight – Fast delivery for urgent orders.

Express Courier – DHL, FedEx, UPS, and TNT services available for small quantity or sample shipments.

Frequently Asked Questions

What is your minimum order quantity (MOQ)?

Our standard MOQ is [30] square meters, but small trial orders are accepted for new customers.

Can you provide custom sizes and mesh counts?

Yes, we offer customization in wire diameter, mesh count, roll length, width, and packaging.

What is the delivery time?

Usually 7–15 days for standard sizes, 20–30 days for large or customized orders.

Do you offer free samples?

Small samples are free, with customers covering the courier cost.

Which payment methods do you accept?

T/T, L/C, and PayPal for small orders.

How do you ensure product quality?

100% inspection before packing, with quality reports available on request.

Custom Metal Mesh Solutions for Your Industry

Contact us today for tailored specifications and a prompt quotation.

📧 Email: sales@md-wiremesh.com

📱 WhatsApp: +86-15132829996

🌐 Website: www.mdwiremesh.com

🔗more info : linktr.ee/zcc5886