MD Wire Mesh Featured on PRLog Newswire

MD Wire Mesh, a professional manufacturer from Anping, China, has officially released a new series of high-precision stainless steel woven wire meshes for industrial filtration, separation, and protection applications.

The launch was recently featured on the global press release platform PRLog Newswire, marking another important milestone for the company’s international brand development.

👉 Read the full press release on PRLog

Engineered for Industrial Filtration and Durability

The new woven mesh products are made from high-quality 304, 316, and 316L stainless steel wires, produced using advanced weaving equipment and strict inspection procedures.

The product range includes plain weave, twill weave, and Dutch weave meshes — each designed for precise filtration, stable structure, and long service life.

These woven meshes are widely used in:

Oil and gas filtration systems

Chemical processing and equipment protection

Food and beverage filtration

Environmental and water treatment industries

About MD Wire Mesh

Located in Anping, China — the world’s largest wire mesh manufacturing base — MD Wire Mesh (Maidong Metal Wire Mesh Products Co., Ltd.) specializes in producing:

Stainless steel woven wire mesh

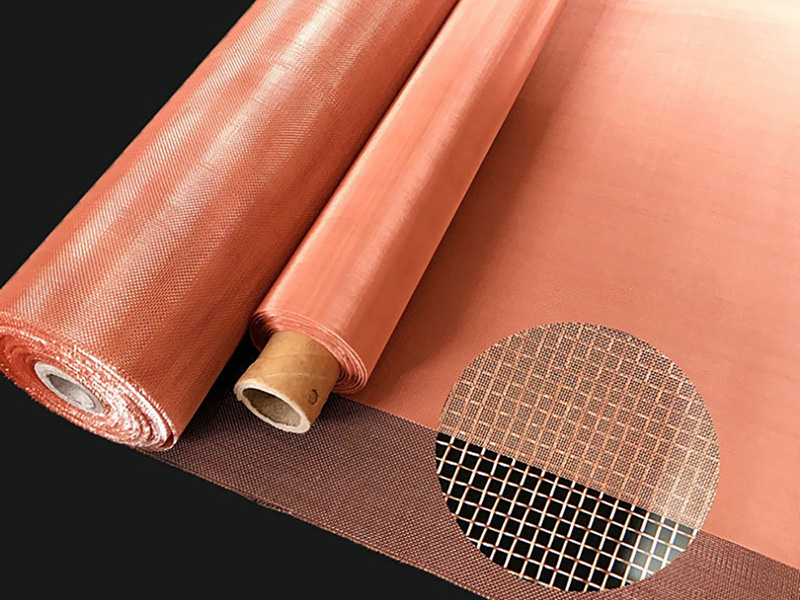

Copper mesh

Perforated metal and welded mesh

Filter elements and deep-processed mesh products

With advanced manufacturing lines and over 10 years of export experience, MD Wire Mesh provides OEM and custom-made filtration solutions for industrial clients across the Middle East, Europe, and South America.

Learn More

For more details or inquiries about customized woven mesh solutions, please contact:

📧 Email: sales@md-wiremesh.com

🌐 Website: www.mdwiremesh.com

📱 WhatsApp: +86-15132829996

🔗 More Info: linktr.ee/zcc5886