Why Stainless Steel Wire Mesh Is the Backbone of Modern Industrial Filtration

Introduction

In today’s industrial world, where precision and reliability are non-negotiable, stainless steel wire mesh has emerged as one of the most trusted materials for filtration and screening. From separating fine particles in chemical processing to ensuring purity in food and beverage production, stainless steel mesh plays a vital role in countless industries. Its unique combination of strength, durability, and corrosion resistance makes it far superior to many alternative materials.

What Is Stainless Steel Wire Mesh?

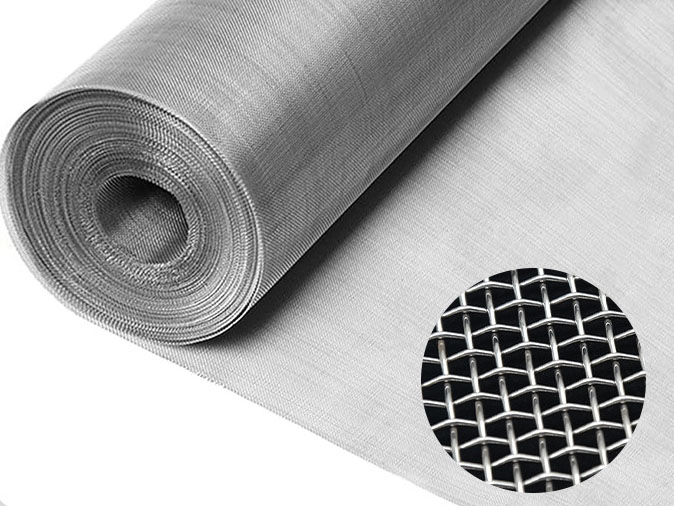

Stainless steel wire mesh is a woven or welded structure created from stainless steel wires. The wires can vary in diameter and mesh opening size, allowing the material to be customized for multiple purposes:

Woven Wire Mesh – produced like fabric, offering uniform openings.

Welded Wire Mesh – wires are welded at every intersection, making it rigid and strong.

Dutch Weave Mesh – features a special weaving style for ultra-fine filtration.

This versatility is what allows stainless steel mesh to serve as a backbone in industrial filtration systems.

Key Advantages of Stainless Steel Wire Mesh

1. Superior Corrosion Resistance

Unlike carbon steel or galvanized mesh, stainless steel can withstand harsh environments, including exposure to acids, alkalis, and high moisture. This makes it ideal for industries such as chemical processing, oil & gas, and water treatment.

2. High Mechanical Strength

Even with fine wires, stainless steel maintains excellent tensile strength. It resists deformation under pressure, which is critical when dealing with high-flow filtration systems.

3. Longevity and Cost Efficiency

Though stainless steel wire mesh may cost more upfront than plastic or mild steel options, its long lifespan reduces replacement frequency, offering long-term savings.

4. Heat and Temperature Resistance

It performs reliably in high-temperature environments where plastics or other metals would fail, such as in furnace filters or catalytic converters.

5. Easy to Clean and Reuse

Stainless steel mesh can be backwashed, cleaned with chemicals, or sterilized without losing structural integrity, making it highly sustainable.

Industrial Applications

✅ Chemical and Petrochemical Industry

Used for separating catalysts, filtering chemicals, and protecting sensitive equipment.

✅ Food and Beverage Industry

Ensures hygiene in filtering ingredients like sugar, flour, and liquids. Stainless steel’s non-toxic nature and easy cleaning process meet global food safety standards.

✅ Water Treatment

Stainless steel mesh filters out impurities, sand, and debris in municipal and industrial water systems, providing clean and safe water.

✅ Mining and Quarrying

Heavy-duty stainless steel mesh screens are used for sorting and grading minerals, ensuring high efficiency and low downtime.

✅ Construction and Architecture

Beyond filtration, woven and welded wire mesh is used in building facades, safety barriers, and reinforcement.

Choosing the Right Stainless Steel Wire Mesh

When selecting stainless steel mesh for industrial filtration, consider the following factors:

Mesh Count (aperture size) – defines the particle size that can pass through.

Wire Diameter – determines mechanical strength and flow rate.

Grade of Stainless Steel – SS304 for general use, SS316/SS316L for marine or chemical environments.

Fabrication Needs – whether the mesh will be cut, welded, or formed into filter cartridges, cones, or discs.

Why Partner With Maidong Wire Mesh?

At Maidong Metal Wire Mesh Products Co., Ltd., we specialize in manufacturing and exporting high-quality stainless steel wire mesh tailored to industrial filtration. Our expertise covers:

Woven wire mesh in stainless steel, copper, and Dutch weave types.

Perforated metal, crimped mesh, and welded mesh.

Fabricated products such as filter cartridges, coffee filters, and BBQ meshes.

Deep processing services including slitting, cutting, welding, and stamping.

🌐 Learn more at: www.mdwiremesh.com

📱 WhatsApp: +86-15132829996

Conclusion

In a world where industries demand efficiency, safety, and precision, stainless steel wire mesh stands out as a material that meets and exceeds expectations. Its strength, durability, and adaptability ensure it remains an essential solution for industrial filtration today and in the future.