Title:

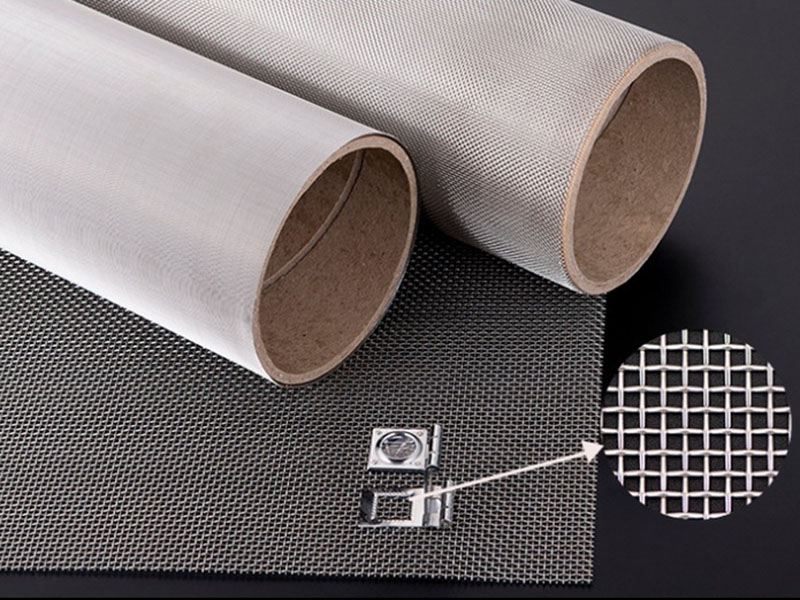

How to Choose the Right Stainless Steel Mesh for Filtration and Screening

Excerpt:

Choosing the right stainless steel mesh is crucial for performance, durability, and precision in industrial filtration. Here’s what to consider.

Content:

When selecting stainless steel mesh for industrial or commercial use, there are several key factors to consider. The right mesh affects not only the filtration accuracy but also corrosion resistance, lifespan, and strength.

1. Mesh Count & Opening Size

The mesh count (number of wires per inch) and opening size determine the filtration level. For fine filtration, a higher mesh count such as 100×100 or 200×200 is used. For general screening, 20×20 or 40×40 may be sufficient.

2. Wire Diameter & Strength

Thicker wire diameters offer greater strength and pressure resistance. Thinner wires provide finer filtration but may deform under pressure. Always balance mesh count with wire thickness for your application.

3. Material Grade (304 / 316 Stainless Steel)

- 304 SS is cost-effective and suitable for general use.

- 316 SS has better corrosion resistance, ideal for marine or chemical environments.

4. Weave Type

- Plain weave: most common, simple square pattern.

- Twilled weave: tighter structure for fine filtration.

- Dutch weave: designed for precise micro-filtration with different warp/weft sizes.

5. Application-Specific Factors

- Air Filtration: needs lightweight mesh, often plain weave

- Oil Filtration: requires strength + chemical resistance

- Water Screens: corrosion resistance is key

Conclusion:

Choosing the right stainless steel mesh ensures performance, durability, and cost-efficiency. At Maidong Metal Mesh, we offer customized solutions based on your industry and application.

📩 Need help choosing the right mesh? Contact us now →