Woven Wire Mesh as a Durable Filter Medium in Industrial Filtration Systems

In industrial filtration systems, the choice of filter media plays a critical role in ensuring long-term process stability and operational reliability. Beyond filtration efficiency alone, filter materials must withstand harsh working conditions such as high temperatures, chemical exposure, pressure fluctuations, and repeated cleaning cycles. For many industrial applications, woven wire mesh has proven to be a dependable and practical filter medium.

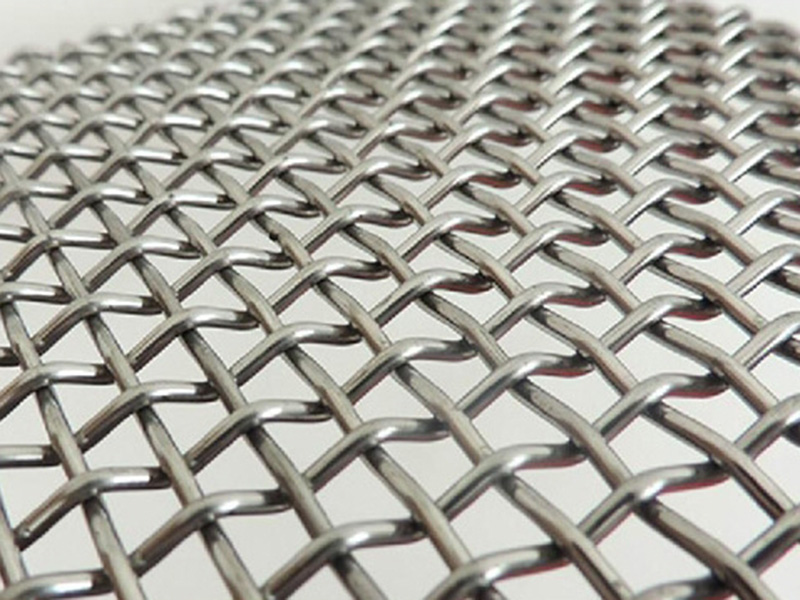

Unlike disposable filter materials, woven wire mesh provides a stable mechanical structure that maintains its shape and filtration characteristics over time. Its rigid construction allows it to resist deformation during backwashing or continuous operation, making it suitable for systems that require consistent performance and extended service life.

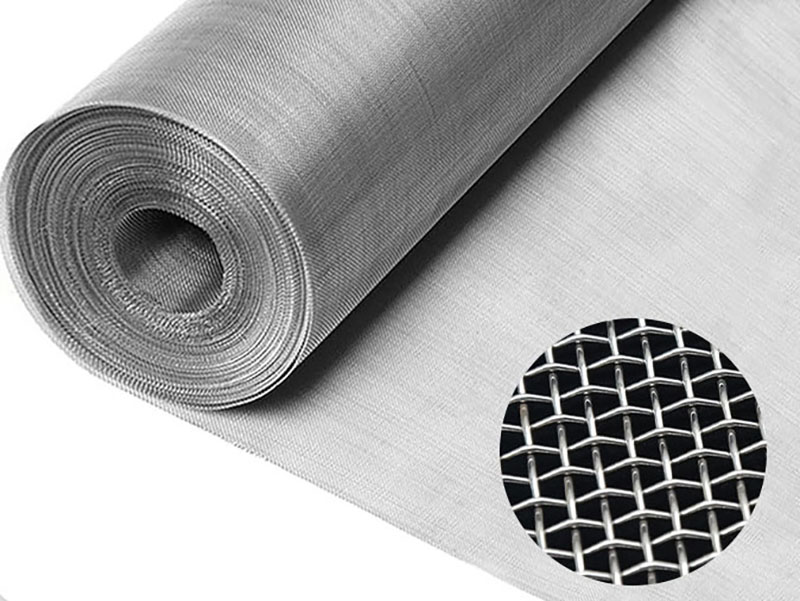

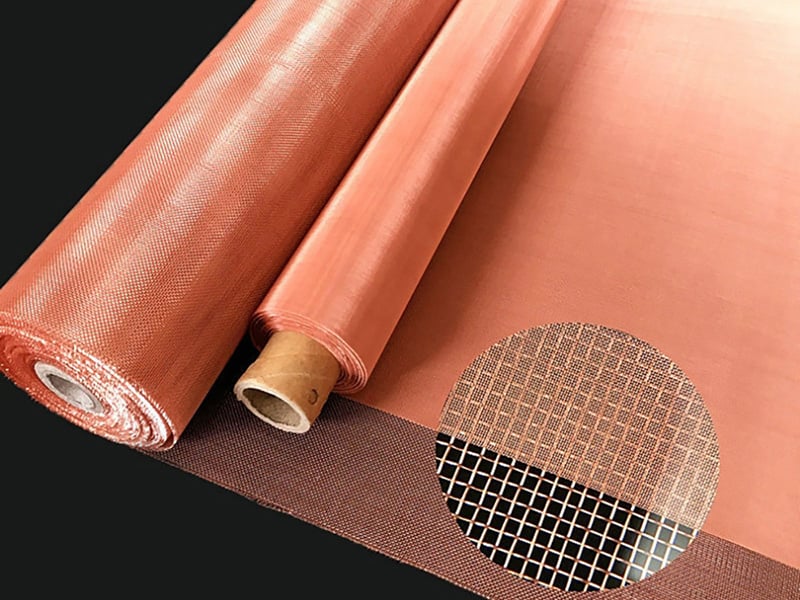

Stainless steel woven wire mesh is widely used in industrial filtration due to its corrosion resistance and thermal stability. It can operate effectively in demanding environments where polymer or fiber-based materials may degrade or fail. As a result, woven wire mesh is commonly integrated into filtration components such as filter cartridges, filter tubes, and screening assemblies.

In industrial filtration design, woven wire mesh often serves as the primary filter medium, supporting the overall structure of filtration elements while allowing precise control of flow and particle retention. Typical application areas include chemical processing, oil and gas systems, industrial water treatment, and food and beverage production, where durability and hygiene are essential.

When selecting woven wire mesh for filtration applications, factors such as mesh structure, wire diameter, material grade, and surface finish should be carefully considered. These parameters influence not only filtration behavior but also cleaning efficiency and operational lifespan. Manufacturers specializing in woven wire mesh for industrial filtration focus on consistent weaving quality and material traceability to meet diverse system requirements.

MD Wire Mesh supplies a range of woven wire mesh products designed for use as filter media in industrial filtration and separation systems. The company supports filtration projects by providing woven wire mesh materials suitable for integration into custom filtration components across various industries.

For more information about woven wire mesh products used in industrial filtration applications,