Stainless Steel Woven Wire Mesh in Industrial Cooling and Ventilation Systems

As industrial infrastructure continues to expand, cooling and ventilation systems are becoming increasingly critical for maintaining stable and reliable operation. In environments such as data centers, power facilities, and energy-related industrial plants, cooling systems often operate continuously, placing higher demands on airflow control and filtration materials.

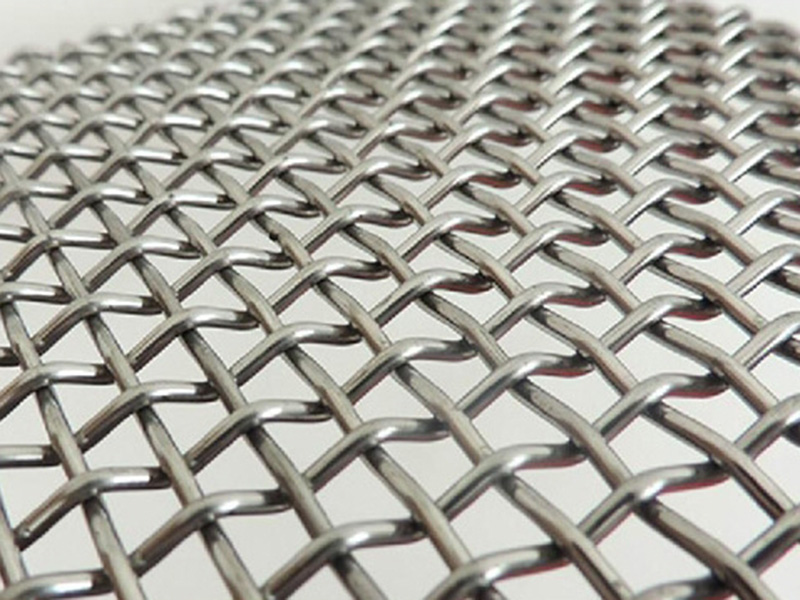

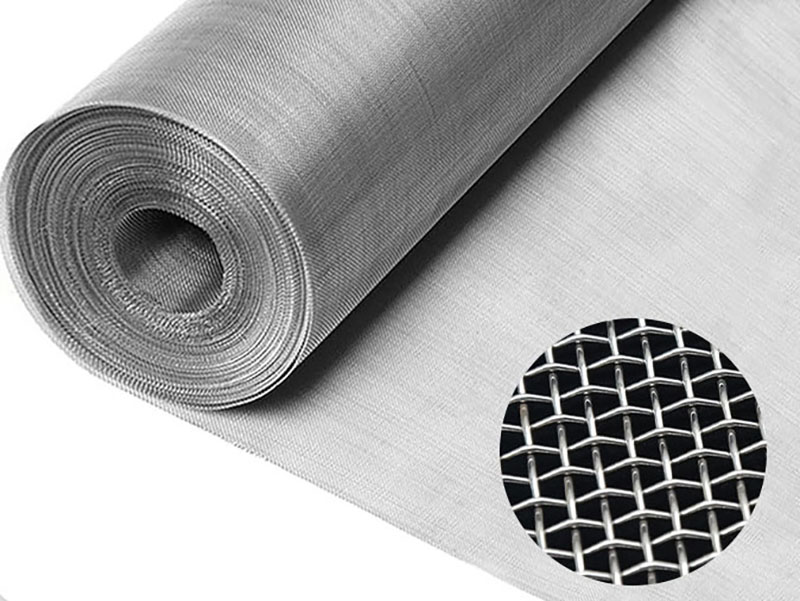

Stainless steel woven wire mesh is widely used in industrial cooling and ventilation applications due to its structural stability, uniform openings, and resistance to heat and corrosion. Unlike disposable filter materials, woven wire mesh maintains consistent airflow performance over long operating cycles, making it suitable for continuous-run systems.

Role of Woven Wire Mesh in Cooling Systems

In industrial cooling systems, stainless steel woven wire mesh is commonly applied as ventilation protection screens, airflow management layers, and pre-filtration components. The woven structure allows sufficient air passage while preventing dust, debris, and foreign particles from entering sensitive equipment areas.

For data centers and energy infrastructure, stable airflow is essential to prevent overheating and reduce unplanned downtime. Stainless steel mesh supports controlled airflow distribution while maintaining mechanical strength under constant air pressure and temperature variation.

Material Selection and Performance

Material selection is based on operating conditions and environmental requirements. Stainless steel grades such as 304 and 316 are commonly used for their corrosion resistance and durability in humid or high-temperature environments. Mesh count and wire diameter can be adjusted depending on whether the application focuses on airflow protection, structural support, or additional filtration performance.

Compared with non-metallic filter media, stainless steel woven wire mesh is less prone to deformation and degradation during long-term use. This stability allows cooling systems to maintain predictable performance and reduces the frequency of material replacement.

Maintenance and Reusability Advantages

One of the key advantages of stainless steel woven wire mesh is its reusability. After cleaning or routine maintenance, the mesh can return to service without significant loss of performance. This reduces consumable costs and supports more predictable maintenance schedules in industrial facilities where downtime must be minimized.

Reusable metal mesh filtration also aligns with increasing requirements for sustainable and environmentally responsible industrial operation, especially in large-scale infrastructure projects.

Applications in Data Centers and Energy Infrastructure

As data centers and energy systems continue to grow in scale and complexity, demand is increasing for cooling and ventilation materials that offer long service life and stable performance. Stainless steel woven wire mesh remains a proven solution for industrial environments where reliability, durability, and consistent airflow are essential.

By combining mechanical strength with flexible fabrication options, woven wire mesh can be integrated into a wide range of cooling and ventilation system designs, supporting long-term industrial operation.