Precision Woven Mesh for Industrial Filtration and Separation

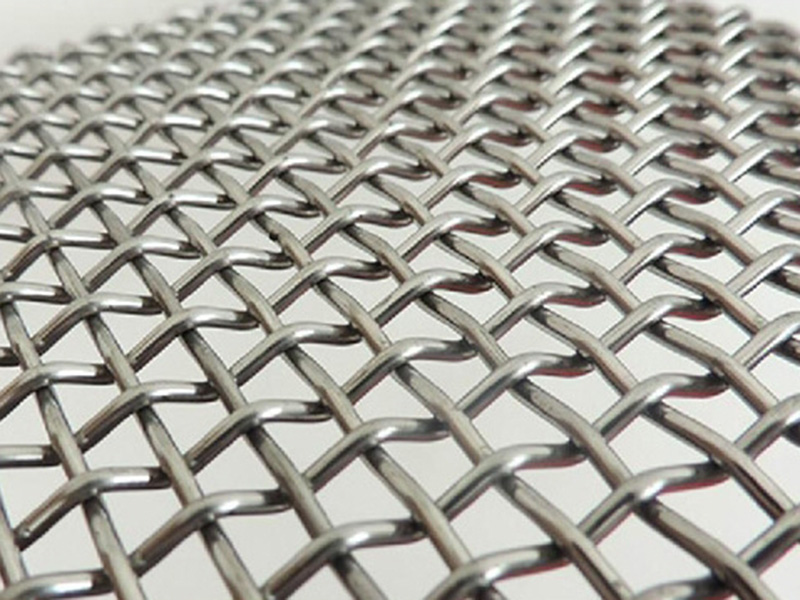

Precision woven mesh is widely used in industrial filtration and separation systems where accuracy, consistency, and long-term stability are required. Compared with standard woven wire mesh, precision woven mesh is manufactured with tighter control over mesh count, wire diameter, and opening size to meet demanding industrial specifications.

As a precision woven mesh manufacturer, this type of woven wire mesh is designed for applications in chemical processing, oil and gas filtration, and fine particle separation, where reliable filtration performance directly affects system efficiency and operating safety.

What Is Precision Woven Mesh?

Precision woven mesh refers to woven wire mesh produced under controlled manufacturing conditions to achieve uniform openings and repeatable performance. Unlike general-purpose wire mesh, precision woven mesh focuses on filtration accuracy rather than decorative or structural use.

Key characteristics of precision woven mesh include:

Controlled mesh count and opening size

Consistent wire diameter tolerance

Stable woven structure

Predictable filtration performance

Precision woven mesh is commonly manufactured from stainless steel materials such as 304, 316, and 316L, which provide corrosion resistance, mechanical strength, and durability in industrial environments.

Manufacturing Capabilities of Precision Woven Mesh

Manufacturing precision woven mesh requires strict process control throughout wire selection, weaving, and inspection. Small variations in wire diameter or weaving tension can significantly affect filtration performance.

Our manufacturing capabilities for precision woven mesh focus on:

In-house wire weaving with controlled tension

Accurate mesh count and wire diameter control

Uniform mesh openings across full roll width

Quality inspection to ensure consistency between batches

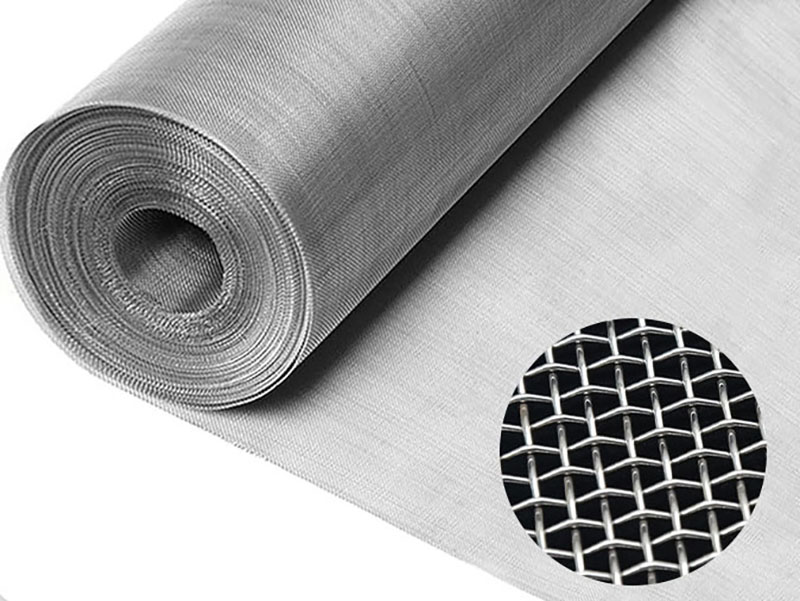

Precision woven wire mesh can be supplied in multiple formats, including rolls, flat sheets, and cut-to-size pieces, depending on application requirements. This flexibility supports both standard filtration systems and customized industrial solutions.

Materials and Specifications

Precision woven mesh is available in a range of materials and specifications to match different operating conditions.

Common Materials

Stainless Steel 304

Stainless Steel 316 / 316L

Supply Forms

Rolls

Sheets

Cut-to-size mesh

Mesh count, wire diameter, and mesh opening can be customized based on filtration requirements and system design.

Industrial Applications

Precision woven mesh is widely used across industries that require reliable filtration and separation performance.

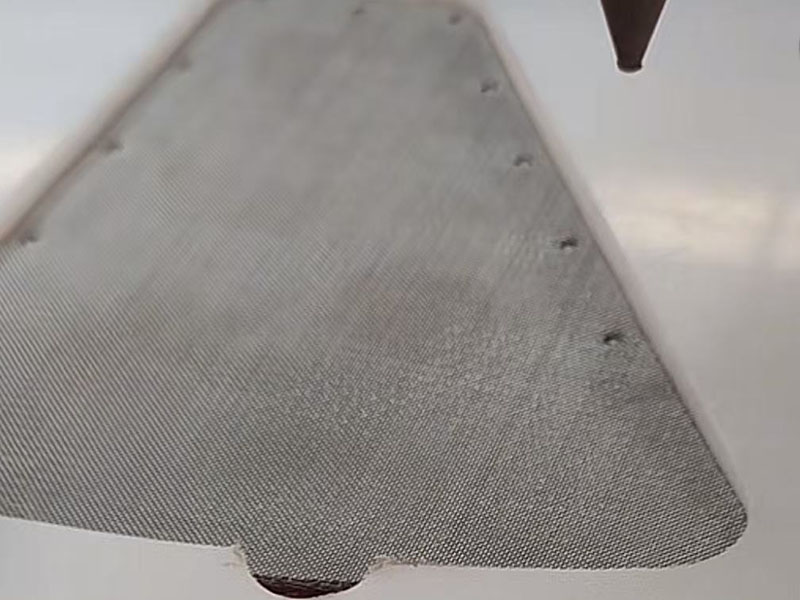

Chemical Industry Separation

In chemical processing systems, precision woven mesh is used for solid–liquid separation, catalyst support layers, and filtration components. Uniform openings help maintain stable flow rates and consistent separation efficiency.

Oil and Gas Filtration

Precision woven wire mesh is commonly applied in oil filtration systems, drilling fluid filtration, and equipment protection. Accurate mesh structure supports effective particle control while maintaining flow performance.

Fine Filtration Systems

High mesh count precision woven mesh is suitable for fine filtration applications where micron-level particle control is required without compromising mechanical stability.

Why Choose a Precision Woven Mesh Manufacturer?

Selecting a specialized precision woven mesh manufacturer offers advantages beyond basic product supply.

Consistent filtration performance

Stable production quality

Technical support for mesh selection

Flexibility for OEM and custom requirements

A reliable manufacturing partner helps reduce operational risk and ensures long-term system reliability.

Precision Woven Mesh for Industrial Use

Precision woven mesh plays a critical role in industrial filtration and separation systems. Manufacturing accuracy, material selection, and process control all contribute to final performance.

By sourcing from an experienced precision woven mesh manufacturer, industrial users can achieve stable, predictable filtration results in chemical processing, oil and gas operations, and fine filtration applications.