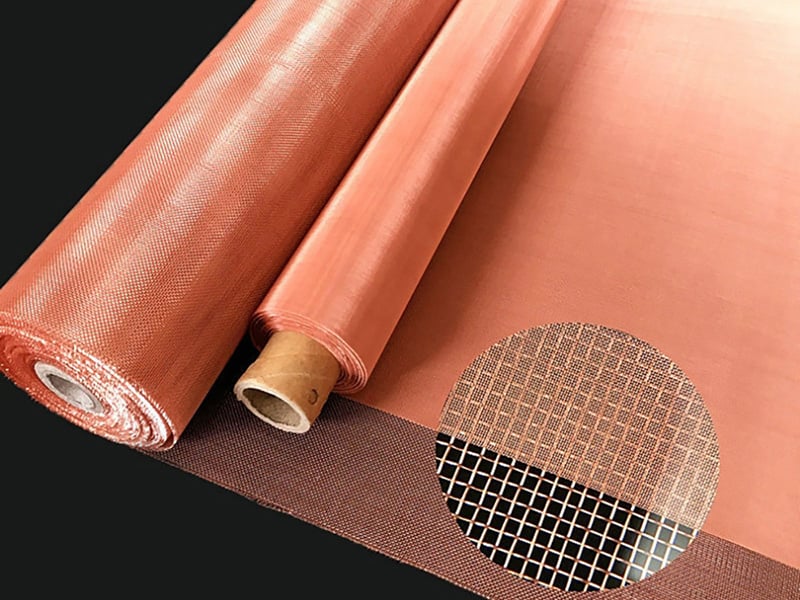

Copper woven mesh is made of high-conductivity copper wires with excellent ductility and thermal stability. It offers uniform aperture accuracy, good corrosion resistance, and reliable shielding performance. Common weave types include plain weave and twill weave.

Copper mesh is widely used in EMI shielding, filtration, particle separation, laboratory screening, electronic components protection, and various industrial applications.

It can be fabricated into mesh rolls, filter tubes, discs, pleated elements, and custom-shaped filter components.

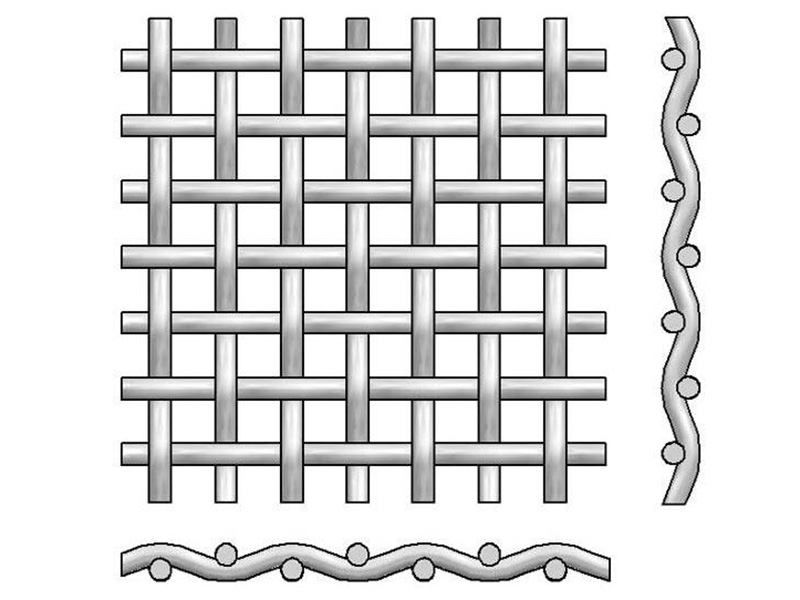

Plain weave is the most widely used structure with balanced warp and weft wires. It provides stable opening size, smooth surface, and excellent conductivity.

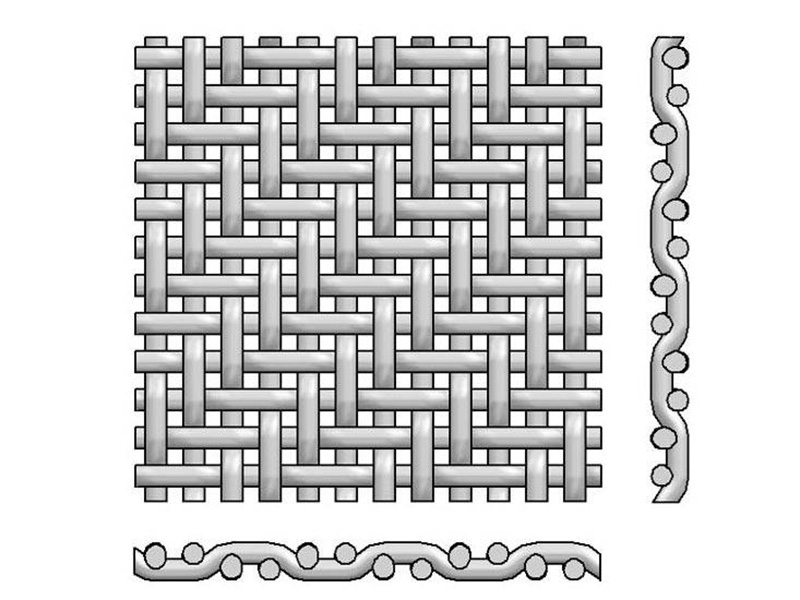

Twill weave allows tighter openings and higher strength by letting each wire pass over two wires. It’s suitable for finer filtration and precision shielding.

Material: H62 / H65 brass

Mesh count: 2–200

Width: 0.6–1.6 m

Properties: Good ductility, corrosion-resistant, non-magnetic; ideal for filtering and decorative use.

Material: phosphor bronze wire

Mesh count: 2–400

Width: 0.6–1.6 m

Properties: Wear-resistant, acid-resistant, non-magnetic; ideal for fine filtration.

| Mesh Count | Wire Diameter | Mesh Opening | Open Area | ||

|---|---|---|---|---|---|

| inch | mm | inch | mm | ||

| 1 × 1 | 0.08 | 2.03 | 0.92 | 23.37 | 85 |

| 1 × 1 | 0.118 | 3 | 0.882 | 22.4 | 78 |

| 2 × 2 | 0.063 | 1.6 | 0.437 | 11.1 | 76 |

| 2 × 2 | 0.059 | 1.5 | 0.441 | 11.2 | 78 |

| 3 × 3 | 0.047 | 1.2 | 0.286 | 7.27 | 74 |

| 4 × 4 | 0.039 | 1 | 0.211 | 5.35 | 71 |

| 5 × 5 | 0.039 | 1 | 0.161 | 4.08 | 65 |

| 6 × 6 | 0.035 | 0.9 | 0.131 | 3.33 | 62 |

| 7 × 7 | 0.031 | 0.8 | 0.111 | 2.83 | 61 |

| 8 × 8 | 0.028 | 0.71 | 0.097 | 2.46 | 60 |

| 10 × 10 | 0.024 | 0.6 | 0.076 | 1.94 | 58 |

| 12 × 12 | 0.02 | 0.508 | 0.063 | 1.6 | 58 |

| 12 × 12 | 0.022 | 0.55 | 0.062 | 1.57 | 55 |

| 14 × 14 | 0.02 | 0.508 | 0.051 | 1.3 | 52 |

| 16 × 16 | 0.018 | 0.457 | 0.0445 | 1.13 | 51 |

| 16 × 16 | 0.02 | 0.5 | 0.043 | 1.09 | 47 |

| 18 × 18 | 0.017 | 0.432 | 0.0386 | 0.98 | 48 |

| 20 × 20 | 0.02 | 0.508 | 0.03 | 0.76 | 36 |

| 20 × 20 | 0.016 | 0.4 | 0.034 | 0.87 | 47 |

| 20 × 20 | 0.018 | 0.45 | 0.032 | 0.82 | 42 |

| 24 × 24 | 0.014 | 0.35 | 0.028 | 0.71 | 45 |

| 30 × 30 | 0.012 | 0.305 | 0.0213 | 0.54 | 41 |

| 30 × 30 | 0.01 | 0.25 | 0.023 | 0.6 | 50 |

| 40 × 40 | 0.01 | 0.254 | 0.015 | 0.38 | 36 |

| 40 × 40 | 0.008 | 0.2 | 0.017 | 0.44 | 47 |

| 50 × 50 | 0.008 | 0.203 | 0.012 | 0.31 | 37 |

| 50 × 50 | 0.007 | 0.18 | 0.013 | 0.33 | 42 |

| 60 × 60 | 0.007 | 0.178 | 0.0097 | 0.25 | 34 |

| 60 × 60 | 0.006 | 0.16 | 0.01 | 0.26 | 38 |

| 60 × 60 | 0.007 | 0.19 | 0.009 | 0.23 | 30 |

| 80 × 80 | 0.005 | 0.12 | 0.008 | 0.2 | 39 |

| 100 × 100 | 0.0045 | 0.11 | 0.0055 | 0.14 | 30 |

| 100 × 100 | 0.0035 | 0.09 | 0.0065 | 0.17 | 43 |

| 100 × 100 | 0.004 | 0.1 | 0.008 | 0.15 | 36 |

| 120 × 120 | 0.0037 | 0.09 | 0.0064 | 0.12 | 31 |

| 120 × 120 | 0.002 | 0.06 | 0.007 | 0.18 | 56 |

| 120 × 120 | 0.003 | 0.08 | 0.005 | 0.13 | 38 |

| 150 × 150 | 0.0026 | 0.066 | 0.0041 | 0.1 | 37 |

| 150 × 150 | 0.002 | 0.06 | 0.004 | 0.11 | 42 |

| 150 × 150 | 0.002 | 0.05 | 0.005 | 0.12 | 50 |

| 160 × 160 | 0.0025 | 0.064 | 0.0038 | 0.1 | 36 |

| 160 × 160 | 0.002 | 0.04 | 0.005 | 0.12 | 56 |

| 180 × 180 | 0.0023 | 0.058 | 0.0033 | 0.08 | 35 |

| 180 × 180 | 0.002 | 0.05 | 0.004 | 0.09 | 41 |

| 180 × 180 | 0.002 | 0.04 | 0.004 | 0.1 | 51 |

| 200 × 200 | 0.002 | 0.053 | 0.003 | 0.07 | 32 |

| 200 × 200 | 0.002 | 0.04 | 0.003 | 0.09 | 48 |

| 250 × 250 | 0.002 | 0.04 | 0.002 | 0.06 | 36 |

| 250 × 250 | 0.001 | 0.035 | 0.003 | 0.07 | 44 |

| 250 × 250 | 0.001 | 0.03 | 0.003 | 0.07 | 49 |

| 300 × 300 | 0.0051 | 0.038 | 0.0018 | 0.05 | 30 |

| 325 × 325 | 0.0014 | 0.036 | 0.0017 | 0.043 | 30 |

| 400 × 400 | 0.001 | 0.025 | 0.0015 | 0.37 | 88 |

| Mesh | Wire Diameter | Width of Opening | Open Area | ||

|---|---|---|---|---|---|

| (in.) | (mm) | (in) | (mm) | ||

| 2 × 2 | 0.063 | 1.6 | 0.437 | 11.1 | 76.4 |

| 3 × 3 | 0.063 | 1.6 | 0.27 | 6.85 | 65.6 |

| 4 × 4 | 0.063 | 1.6 | 0.187 | 4.75 | 56 |

| 4 × 4 | 0.047 | 1.2 | 0.203 | 5.156 | 65.9 |

| 6 × 6 | 0.035 | 0.9 | 0.132 | 3.35 | 62.7 |

| 8 × 8 | 0.028 | 0.71 | 0.097 | 2.46 | 60.2 |

| 10 × 10 | 0.025 | 0.6 | 0.075 | 1.9 | 56.3 |

| 12 × 12 | 0.023 | 0.55 | 0.06 | 1.52 | 51.8 |

| 14 × 14 | 0.02 | 0.5 | 0.051 | 1.29 | 51 |

| 16 × 16 | 0.018 | 0.45 | 0.045 | 1.14 | 50.7 |

| 18 × 18 | 0.017 | 0.432 | 0.039 | 0.99 | 48.3 |

| 20 × 20 | 0.016 | 0.4 | 0.034 | 0.85 | 46.2 |

| 24 × 24 | 0.014 | 0.35 | 0.028 | 0.71 | 44.2 |

| 30 × 30 | 0.013 | 0.33 | 0.02 | 0.5 | 37.1 |

| 40 × 40 | 0.01 | 0.25 | 0.015 | 0.38 | 36 |

| 50 × 50 | 0.009 | 0.228 | 0.011 | 0.27 | 30.3 |

| 60 × 60 | 0.0075 | 0.19 | 0.009 | 0.22 | 30.5 |

| 80 × 80 | 0.0055 | 0.14 | 0.007 | 0.17 | 31.4 |

| 100 × 100 | 0.0045 | 0.11 | 0.006 | 0.15 | 30.3 |

| Mesh Count | Wire Diameter | Mesh Opening | Open Area | ||

|---|---|---|---|---|---|

| inch | mm | inch | mm | ||

| 1 × 1 | 0.08 | 2.03 | 0.92 | 23.37 | 85 |

| 1 × 1 | 0.118 | 3 | 0.882 | 22.4 | 78 |

| 2 × 2 | 0.063 | 1.6 | 0.437 | 11.1 | 76 |

| 2 × 2 | 0.059 | 1.5 | 0.441 | 11.2 | 78 |

| 3 × 3 | 0.047 | 1.2 | 0.286 | 7.27 | 74 |

| 4 × 4 | 0.039 | 1 | 0.211 | 5.35 | 71 |

| 5 × 5 | 0.039 | 1 | 0.161 | 4.08 | 65 |

| 6 × 6 | 0.035 | 0.9 | 0.131 | 3.33 | 62 |

| 7 × 7 | 0.031 | 0.8 | 0.111 | 2.83 | 61 |

| 8 × 8 | 0.028 | 0.71 | 0.097 | 2.46 | 60 |

| 10 × 10 | 0.024 | 0.6 | 0.076 | 1.94 | 58 |

| 12 × 12 | 0.02 | 0.508 | 0.063 | 1.6 | 58 |

| 12 × 12 | 0.022 | 0.55 | 0.062 | 1.57 | 55 |

| 14 × 14 | 0.02 | 0.508 | 0.051 | 1.3 | 52 |

| 16 × 16 | 0.018 | 0.457 | 0.0445 | 1.13 | 51 |

| 16 × 16 | 0.02 | 0.5 | 0.043 | 1.09 | 47 |

| 18 × 18 | 0.017 | 0.432 | 0.0386 | 0.98 | 48 |

| 20 × 20 | 0.02 | 0.508 | 0.03 | 0.76 | 36 |

| 20 × 20 | 0.016 | 0.4 | 0.034 | 0.87 | 47 |

| 20 × 20 | 0.018 | 0.45 | 0.032 | 0.82 | 42 |

| 24 × 24 | 0.014 | 0.35 | 0.028 | 0.71 | 45 |

| 30 × 30 | 0.012 | 0.305 | 0.0213 | 0.54 | 41 |

| 30 × 30 | 0.01 | 0.25 | 0.023 | 0.6 | 50 |

| 40 × 40 | 0.01 | 0.254 | 0.015 | 0.38 | 36 |

| 40 × 40 | 0.008 | 0.2 | 0.017 | 0.44 | 47 |

| 50 × 50 | 0.008 | 0.203 | 0.012 | 0.31 | 37 |

| 50 × 50 | 0.007 | 0.18 | 0.013 | 0.33 | 42 |

| 60 × 60 | 0.007 | 0.178 | 0.0097 | 0.25 | 34 |

| 60 × 60 | 0.006 | 0.16 | 0.01 | 0.26 | 38 |

| 60 × 60 | 0.007 | 0.19 | 0.009 | 0.23 | 30 |

| 80 × 80 | 0.005 | 0.12 | 0.008 | 0.2 | 39 |

| 100 × 100 | 0.0045 | 0.11 | 0.0055 | 0.14 | 30 |

| 100 × 100 | 0.0035 | 0.09 | 0.0065 | 0.17 | 43 |

| 100 × 100 | 0.004 | 0.1 | 0.008 | 0.15 | 36 |

| 120 × 120 | 0.0037 | 0.09 | 0.0064 | 0.12 | 31 |

| 120 × 120 | 0.002 | 0.06 | 0.007 | 0.18 | 56 |

| 120 × 120 | 0.003 | 0.08 | 0.005 | 0.13 | 38 |

| 150 × 150 | 0.0026 | 0.066 | 0.0041 | 0.1 | 37 |

| 150 × 150 | 0.002 | 0.06 | 0.004 | 0.11 | 42 |

| 150 × 150 | 0.002 | 0.05 | 0.005 | 0.12 | 50 |

| 160 × 160 | 0.0025 | 0.064 | 0.0038 | 0.1 | 36 |

| 160 × 160 | 0.002 | 0.04 | 0.005 | 0.12 | 56 |

| 180 × 180 | 0.0023 | 0.058 | 0.0033 | 0.08 | 35 |

| 180 × 180 | 0.002 | 0.05 | 0.004 | 0.09 | 41 |

| 180 × 180 | 0.002 | 0.04 | 0.004 | 0.1 | 51 |

| 200 × 200 | 0.002 | 0.053 | 0.003 | 0.07 | 32 |

| 200 × 200 | 0.002 | 0.04 | 0.003 | 0.09 | 48 |

Copper, brass, and phosphor bronze wire meshes are widely used in electrical shielding, signal protection, precision filtration, insect control, and architectural decoration. Their excellent conductivity, corrosion resistance, and formability make them ideal for both industrial and commercial applications.

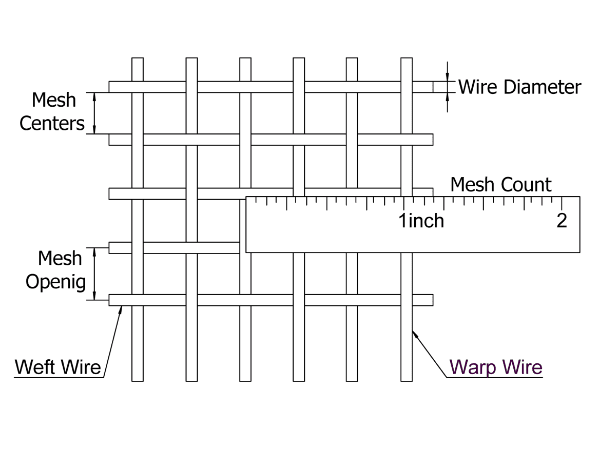

The following glossary explains the fundamental technical terms used to describe stainless steel woven wire mesh, including wire directions, mesh measurements, and structural parameters. These definitions help ensure clear communication when selecting or specifying mesh materials.

Warp:Longitudinal wires running parallel to the mesh length.

Weft (or Woof):Cross wires running perpendicular to the warp wires.

Mesh Count:The number of openings per linear inch, indicating mesh fineness.

Wire Diameter:The thickness of the wire before weaving.

Mesh Opening:The clear distance between two adjacent wires.

Mesh Centers (Pitch):The distance from the center of one wire to the center of the next.

Tell us your mesh count, wire diameter, size and quantity.

📧 Email: sales@md-wiremesh.com

📱 WhatsApp: +86-15132829996

🌐 Website: www.mdwiremesh.com

🔗more info : linktr.ee/zcc5886