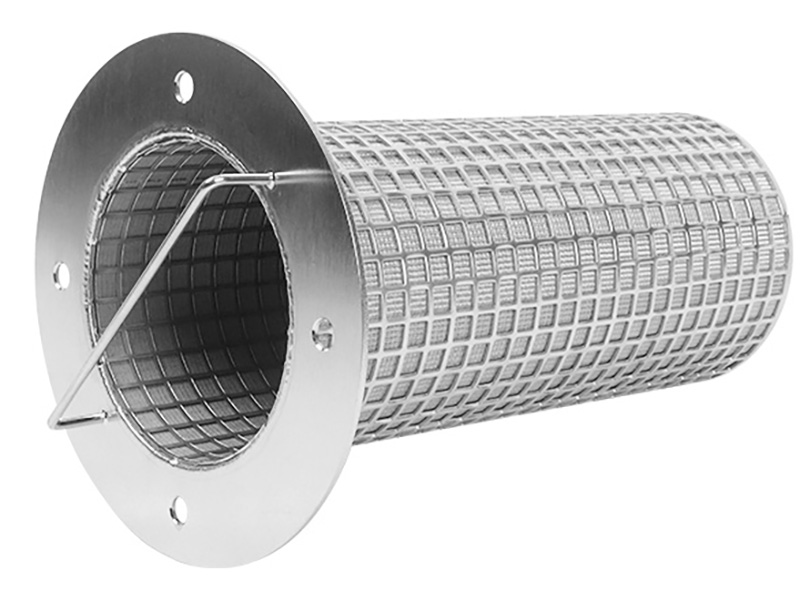

Conical Filter

High-performance stainless steel conical filters with strong mechanical strength, precise filtration, and compact design — ideal for liquid, gas, and powder filtration applications.

Stainless Steel Conical Filter Overview

Maidong stainless steel conical filters are precision-engineered filtration elements designed for high efficiency and durability.

Their cone-shaped structure allows smooth fluid distribution and minimizes flow resistance, providing excellent particle retention and stable performance.

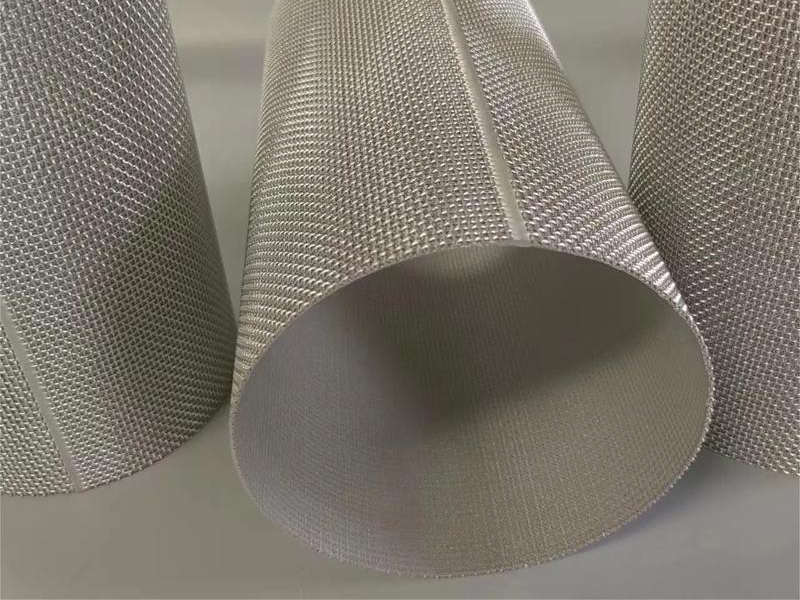

Made from stainless steel woven mesh or perforated metal, the filters offer strong mechanical strength, heat resistance, and reusability.

They can be easily installed, removed, and cleaned, making them ideal for repeated filtration processes.

Conical filters are widely used in chemical processing, petroleum refining, gas filtration, and powder handling industries, where compact installation and reliable separation are required.

Key Features & Advantages

High Filtration Efficiency

The conical structure ensures smooth fluid distribution and consistent particle retention, reducing pressure drop during operation.

Excellent Heat & Corrosion Resistance

Performs reliably in high-temperature or corrosive environments, suitable for chemical, oil, and gas applications.

Easy Cleaning & Reusable

The cone-shaped design allows easy backflushing, ultrasonic, or chemical cleaning, extending service life and reducing downtime.

Customizable Design

Available in different angles, sizes, mesh types, and connection styles to meet OEM and project-specific requirements.

Strong Mechanical Strength

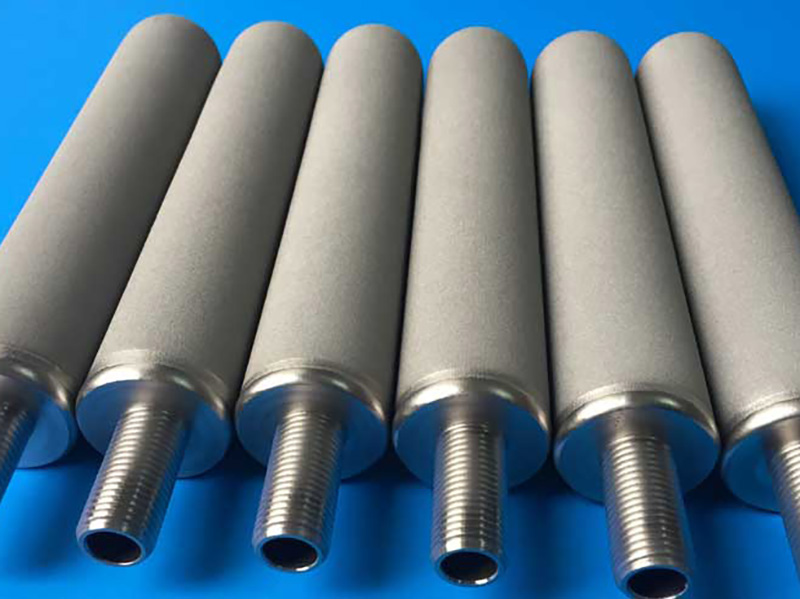

Made of stainless steel 304 or 316L, the filter maintains its shape under pressure and high flow rates for stable performance.

Wide Application Range

Used in filtration of liquids, gases, and powders across chemical, food & beverage, and pharmaceutical industries.

Technical Specifications

Maidong stainless steel conical filters are engineered for compact installation, smooth flow distribution, and reliable separation in liquid, gas, and powder systems.

• Material: Stainless steel 304, 316, 316L (other alloys on request)

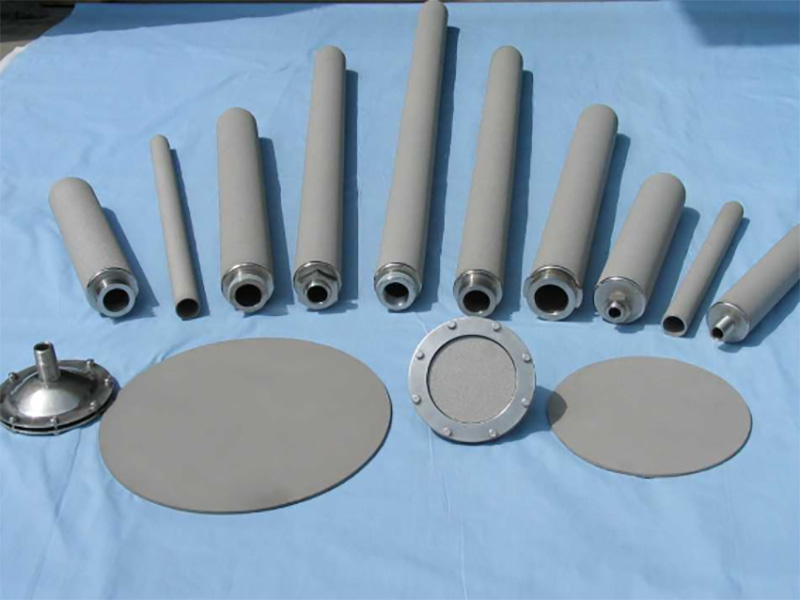

• Filter media: Woven wire mesh, sintered fiber felt, or perforated metal

• Micron rating: 1 – 500 μm (customizable)

• Cone angle: 30°, 45°, 60° (or per drawing)

• Top/OD: 20 – 300 mm

• Height: 50 – 600 mm

• Rim/Flange: Straight rim, rolled edge, or flange ring

• Connection options: Clamp/tri-clamp, flange, threaded, or custom end caps

• Operating pressure: ≤ 20 bar (depending on structure)

• Operating temperature: ≤ 500 °C (material dependent)

• Cleaning methods: Backflushing, ultrasonic, or chemical cleaning

• Surface finish: Pickling, passivation, or polishing

• Packaging: PE bag + carton + pallet (labeling/barcode available)

Contact us for drawings, tolerances, and OEM specifications.

Customization Options

Maidong provides full customization services for stainless steel conical filters to suit different operating environments and OEM requirements.

✔️ **Material Options:** SS304, SS316, SS316L, or customized alloys for high temperature and corrosion resistance.

✔️ **Cone Angle:** Standard 30°, 45°, 60°, or custom angles based on installation space.

✔️ **Micron Rating:** 1–500 μm filtration accuracy, adjustable to medium characteristics.

✔️ **Size & Structure:** Custom diameters, heights, and wall thickness for specific equipment or housings.

✔️ **Connection Types:** Threaded, flanged, clamp, or custom welded connections.

✔️ **Surface Treatment:** Pickling, passivation, or mirror polishing for improved cleanliness and durability.

✔️ **Logo & Packaging:** OEM logo, barcode, and export packaging available upon request.

Contact Maidong Metal Mesh for custom engineering and production of conical filter elements.

Applications

Water Treatment

Used in wastewater and process water purification, ensuring clean and reliable filtration.

Learn More

Chemical Industry

Used in chemical production lines for liquid and gas filtration, protecting process equipment and ensuring product purity.

Learn More

Food & Beverage

Ensures hygiene and precision filtration in brewing, dairy, and beverage processing for food-grade safety.

Learn More

Oil & Gas Industry

Used in drilling mud filtration, gas–liquid separation, and oil refining to protect pipelines and improve production efficiency.

Learn More

Pharmaceutical Industry

Used in sterile filtration, air purification, and liquid-solid separation to meet strict sanitary standards.

Learn More

Power & Energy Industry

Used in turbine lubrication systems, cooling water filtration, and environmental protection equipment to ensure safe and stable operation.

Learn More

Hydraulic & Metallurgy Industry

Provides efficient filtration for hydraulic oil, rolling mills, and smelting processes, preventing contamination and extending equipment life.

Learn More

Plastics & Chemical Fiber Industry

Applied in polymer filtration, extrusion, and fiber spinning processes to ensure material purity and uniform flow.

Learn More

Product Gallery

Start Your Project with Conical filter elements

We guarantee a quick response within 12 hours and a competitive quote.

📧 Email: sales@md-wiremesh.com

📱 WhatsApp: +86-15132829996

🌐 Website: www.mdwiremesh.com

🔗more info : linktr.ee/zcc5886