Plastics & Chemical Fiber Industry Filtration Solutions

High-performance stainless steel and sintered mesh filters designed for polymer filtration, extrusion, and fiber spinning applications — ensuring purity, stability, and smooth production flow.

Reliable Filtration Solutions for the Plastics & Chemical Fiber Industry

In the plastics and chemical fiber industry, filtration is essential for maintaining polymer purity,

ensuring smooth extrusion, and achieving consistent product quality.

Contaminants such as unmelted resin, carbonized particles, and impurities can lead to surface defects,

unstable flow, and machine downtime.

Maidong provides stainless steel wire mesh and sintered filter elements specifically developed for polymer filtration

and fiber spinning applications. These filters are capable of withstanding high temperature, high viscosity,

and continuous operation conditions in extrusion and spinning equipment.

With multi-layer precision filtration structures and easy-to-clean designs,

Maidong filters help improve melt cleanliness, extend screen pack life, and ensure stable, efficient production performance.

Filtration Challenges in Plastics & Chemical Fiber Production

– What filtration problems need to be solved in polymer and fiber production?

In polymer extrusion and fiber spinning, maintaining melt cleanliness is critical for product stability and quality.

High temperature, pressure, and viscosity make filtration challenging, as impurities can cause surface defects,

block nozzles, and lead to frequent shutdowns.

Efficient filtration is necessary to ensure smooth flow, uniform fiber formation, and long-term production reliability.

High Temperature & Viscosity

Polymer melts require filters that can withstand continuous high temperatures and viscous flow without deformation.

Impurities & Carbonization

Unmelted resin, gels, and carbon residues can cause extrusion defects and affect fiber spinning quality.

Pressure & Flow Instability

Improper filtration can lead to flow fluctuations, pressure spikes, and nozzle clogging.

Frequent Screen Replacement

Conventional mesh screens require frequent changes, resulting in downtime and material waste.

Maidong Filtration Solutions for the Plastics & Chemical Fiber Industry

– Precision stainless steel and sintered filters engineered for stable polymer flow, melt cleanliness, and fiber quality.

Maidong provides advanced stainless steel and sintered mesh filters specifically designed for the plastics and chemical fiber industry.

Our filtration solutions ensure polymer purity, uniform melt flow, and consistent extrusion performance.

Using multi-layer sintered mesh structures, these filters deliver excellent resistance to high temperature,

pressure, and chemical corrosion — ideal for polymer filtration, extrusion lines, and fiber spinning machines.

Maidong filter discs, cartridges, and screen packs are widely used in PET, PP, PE, PA, and chemical fiber production lines.

Their washable and reusable designs reduce replacement frequency, lower production costs,

and maintain long-term system stability for continuous, high-precision polymer processing.

Filter Products for Plastics & Chemical Fiber Applications

– High-efficiency stainless steel and sintered filters for polymer melt, extrusion, and spinning systems.

Explore Maidong’s core filtration products designed for plastics and chemical fiber processing.

Our filters ensure high polymer cleanliness, uniform pressure, and stable melt flow during extrusion and spinning.

Each product is built with durable stainless steel or sintered mesh materials,

providing excellent resistance to heat, corrosion, and deformation under continuous operation.

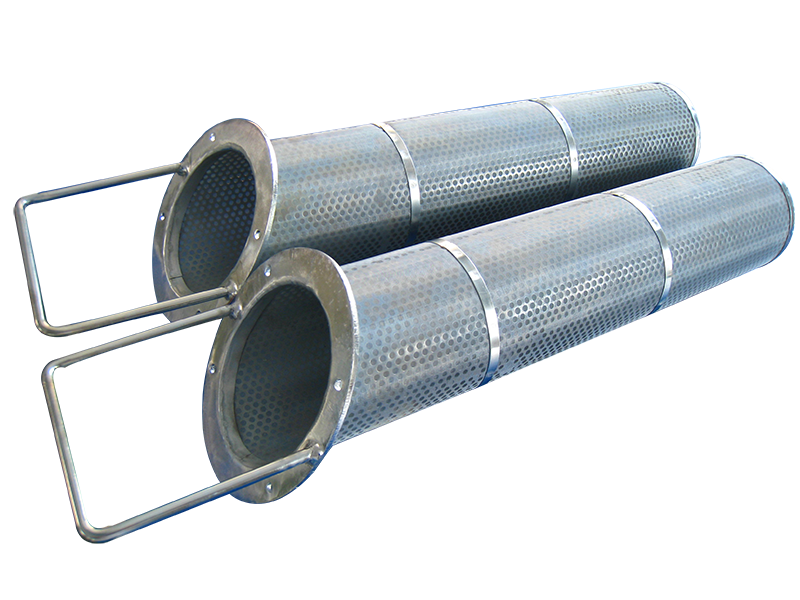

Filter Cartridge

Multi-layer stainless steel cartridges for precision liquid filtration.

Learn More

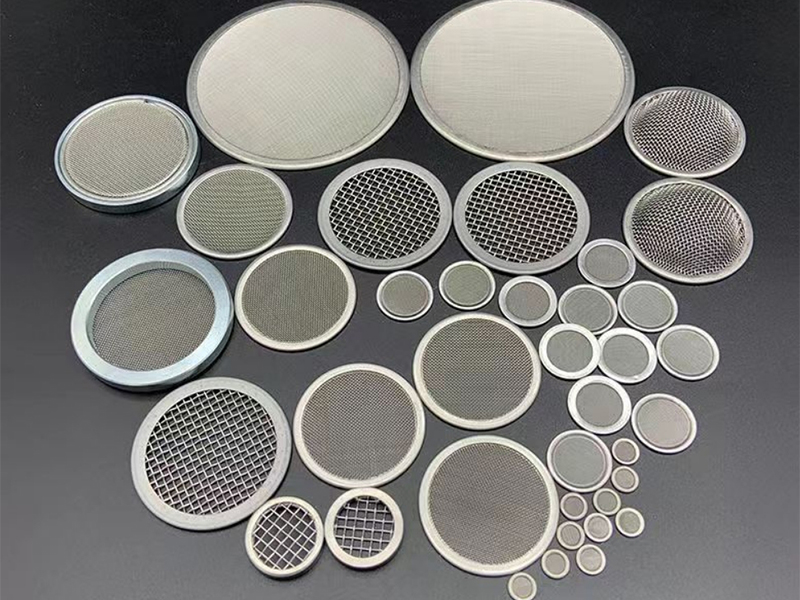

Disc Filter elements

Fine woven or sintered mesh discs for liquid and gas purification.

Learn More

Sintered Filter Cartridge

Rigid sintered metal filters with stable flow and high durability.

Learn More

Pleated Filter Element

Extended surface pleated design for high flow and long service life.

Learn More

Basket Filter

Perforated or mesh-lined basket filters for coarse particle removal.

Learn More

Conical filter

Tapered cone filters for easy installation and efficient pre-filtration.

Learn More

Powder Sintered Filter

Porous sintered tubes for precise filtration and uniform air/liquid flow.

Learn More

Start Your Project with Maidong Wire Mesh Filters

We provide reliable stainless steel filtration solutions for your industry.

Contact us for OEM designs, custom specifications, and free consultation within 12 hours.

📧 Email: sales@md-wiremesh.com

📱 WhatsApp: +86-15132829996

🌐 Website: www.mdwiremesh.com

🔗more info : linktr.ee/zcc5886