Pharmaceutical Filtration Solutions

Reliable stainless steel wire mesh and filter elements designed for pharmaceutical and biotechnology processes — ensuring cleanliness, durability, and GMP compliance.

Reliable Filtration for the Pharmaceutical Industry

Pharmaceutical and biotechnology manufacturing requires extremely high levels of cleanliness, precision, and reliability.

Maidong stainless steel wire mesh and sintered filter elements are specifically engineered to meet GMP and FDA standards — providing stable performance under frequent cleaning, sterilization, and high-pressure conditions.

Our filters are widely used in processes such as fermentation, solvent clarification, sterile air filtration, and liquid-solid separation.

With corrosion resistance, fine filtration accuracy, and easy maintenance, Maidong filter elements ensure consistent product quality and process safety in every stage of pharmaceutical production.

Filtration Challenges in the Pharmaceutical Industry

– What problems need to be solved?

In pharmaceutical and biotechnology manufacturing, filtration systems must guarantee sterility, consistency, and precision under demanding conditions.

Frequent sterilization cycles, exposure to aggressive chemicals, and the need for ultra-fine filtration create major challenges for filter performance and durability.

Sterility and Contamination Control

Pharmaceutical processes require absolute sterility.

Any contamination or microbial growth within filters can compromise product quality and patient safety.

Frequent Sterilization & Cleaning (CIP/SIP)

Filters must withstand high-temperature steam and chemical sterilization cycles without deforming or losing filtration accuracy.

Chemical & Corrosion Resistance

Exposure to acids, solvents, and cleaning agents can corrode ordinary filter materials, reducing their lifespan and reliability.

Precision & Maintenance Cost

High-precision filters are costly to replace.

Reusable stainless steel filters reduce downtime and overall maintenance expenses.

Maidong Filtration Solutions for Pharmaceutical Production

— Advanced stainless steel filters engineered for sterility, precision, and regulatory compliance.

Maidong provides advanced stainless steel wire mesh and sintered filter elements specifically designed for pharmaceutical and biotechnology processes.

Our filters combine multi-layer precision construction with excellent corrosion resistance, ensuring consistent performance under high-pressure, high-temperature, and sterile cleaning conditions (CIP/SIP).

All filter elements are manufactured with smooth, crevice-free surfaces to eliminate contamination risks and meet GMP and FDA hygiene standards.

From raw material preparation to sterile gas filtration and liquid purification, Maidong filtration solutions deliver stability, repeatability, and confidence in critical pharmaceutical production lines.

Filter Products for Pharmaceutical Applications

— Stainless steel filter elements engineered for sterile and high-precision pharmaceutical processes.

Maidong offers a complete range of stainless steel filter elements designed for the strict hygiene and performance demands of the pharmaceutical and biotechnology industries.

Each product provides precise filtration, corrosion resistance, and easy cleaning for long-term, GMP-compliant operation.

Our reusable filter elements replace disposable cartridges to reduce maintenance cost and contamination risk while maintaining full process reliability.

Filter Cartridge

Multi-layer stainless steel cartridges for precision liquid filtration.

Learn More

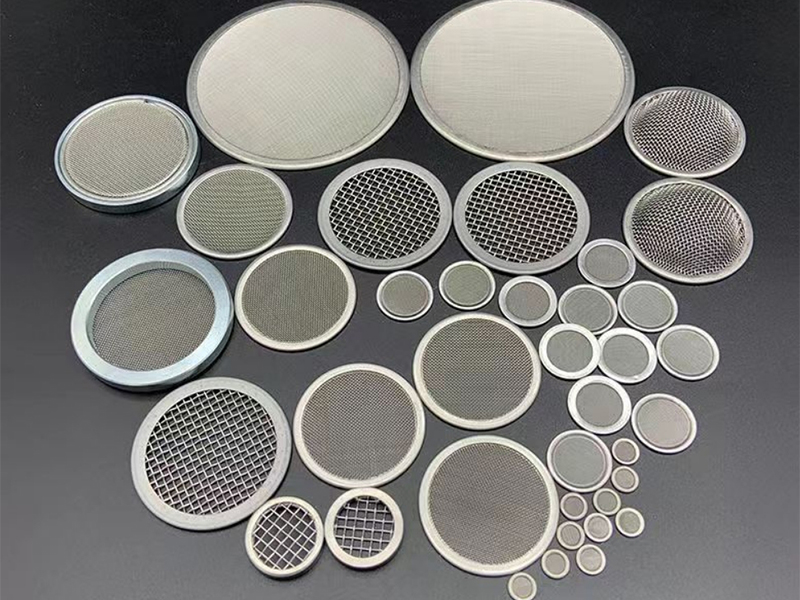

Disc Filter elements

Fine woven or sintered mesh discs for liquid and gas purification.

Learn More

Sintered Filter Cartridge

Rigid sintered metal filters with stable flow and high durability.

Learn More

Pleated Filter Element

Extended surface pleated design for high flow and long service life.

Learn More

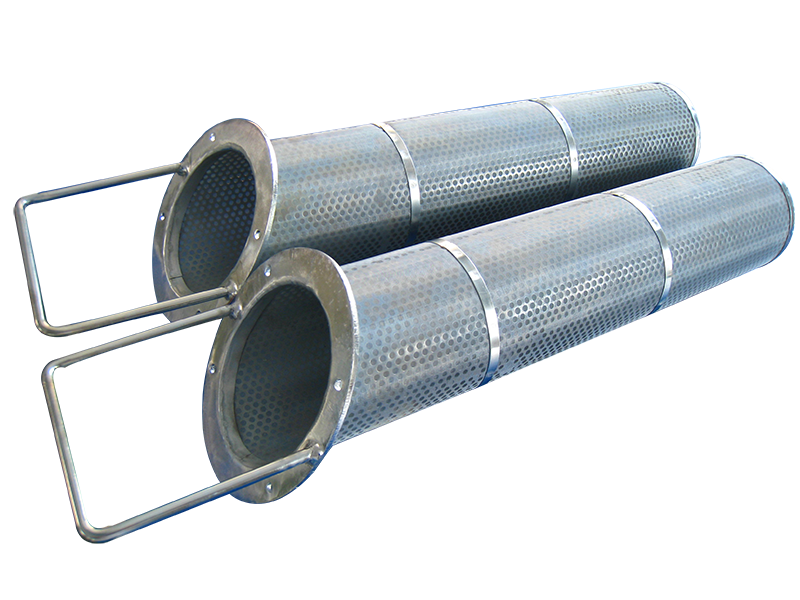

Basket Filter

Perforated or mesh-lined basket filters for coarse particle removal.

Learn More

Conical filter

Tapered cone filters for easy installation and efficient pre-filtration.

Learn More

Powder Sintered Filter

Porous sintered tubes for precise filtration and uniform air/liquid flow.

Learn More

Start Your Project with Maidong Wire Mesh Filters

We provide reliable stainless steel filtration solutions for your industry.

Contact us for OEM designs, custom specifications, and free consultation within 12 hours.

📧 Email: sales@md-wiremesh.com

📱 WhatsApp: +86-15132829996

🌐 Website: www.mdwiremesh.com

🔗more info : linktr.ee/zcc5886