Hydraulic & Metallurgy Industry Filtration Solutions

Durable stainless steel and sintered mesh filters designed for hydraulic and metallurgy applications — ensuring reliable performance in oil, rolling mill, and smelting systems.

Reliable Filtration Solutions for the Hydraulic & Metallurgy Industry

In hydraulic and metallurgy industries, filtration plays a critical role in ensuring the reliability and performance of hydraulic oil systems, rolling mills, and smelting processes.

Contaminants such as metal particles, oxides, and dust can cause serious wear, clogging, and equipment damage.

Maidong provides high-strength stainless steel and sintered mesh filters that can withstand high temperature, pressure, and corrosion in these demanding environments.

Our filtration products are widely used in hydraulic circuits, cooling systems, and molten metal protection applications.

By offering durable, cleanable, and reusable filter designs, Maidong filtration solutions help improve equipment lifespan, reduce maintenance frequency, and maintain production stability in metallurgy plants.

Filtration Challenges in Hydraulic & Metallurgy Systems

– What problems need to be solved?

Hydraulic and metallurgy systems often operate under high pressure, high temperature, and heavily contaminated conditions.

Particles, scale, and metal residues in hydraulic oil or cooling fluids can cause system wear, leakage, or even complete equipment failure.

Proper filtration is essential to maintain efficiency, reduce downtime, and extend component lifespan.

High Pressure & Temperature Conditions

Hydraulic systems and smelting environments require filters that resist heat and pressure without deformation.

Metal Particle Contamination

Small metallic impurities from wear and processing can clog filters and damage valves or pumps.

Oxidation & Corrosion

Exposure to high heat and oxygen accelerates oxidation, leading to corrosion and shortened filter life.

Frequent Maintenance & System Downtime

Inefficient filtration increases cleaning frequency and disrupts production continuity.

Maidong Filtration Solutions for the Hydraulic & Metallurgy Industry

– Advanced stainless steel and sintered filters designed for reliability and efficiency in hydraulic and metallurgical processes.

Maidong offers high-quality stainless steel wire mesh and sintered metal filters tailored for hydraulic and metallurgy applications.

Our filtration products are engineered to operate reliably under extreme pressure, high temperature, and heavy contamination conditions.

These filters play a vital role in protecting pumps, valves, and hydraulic circuits from metal wear particles, ensuring smooth operation of rolling mills and forging equipment.

They are also widely applied in cooling systems and molten metal filtration to prevent slag, oxide, and impurities from affecting production quality.

By using multi-layer sintered mesh structures and corrosion-resistant materials, Maidong filters provide long service life, stable flow, and easy maintenance.

Our reusable and customizable filter elements help customers improve operational efficiency and maintain cleaner, safer production environments.

Filter Products for Hydraulic & Metallurgy Applications

– High-performance stainless steel and sintered filters for hydraulic oil systems and metallurgy processing equipment.

Discover Maidong’s essential filtration products developed for the hydraulic and metallurgy industry.

Each filter is designed to handle high pressure, temperature, and heavy contamination environments,

providing strong corrosion resistance, stable performance, and long service life.

Our stainless steel and sintered mesh filters are widely used in hydraulic oil systems, rolling mills,

smelting workshops, and cooling circuits — ensuring efficient filtration and reliable protection for critical components.

Filter Cartridge

Multi-layer stainless steel cartridges for precision liquid filtration.

Learn More

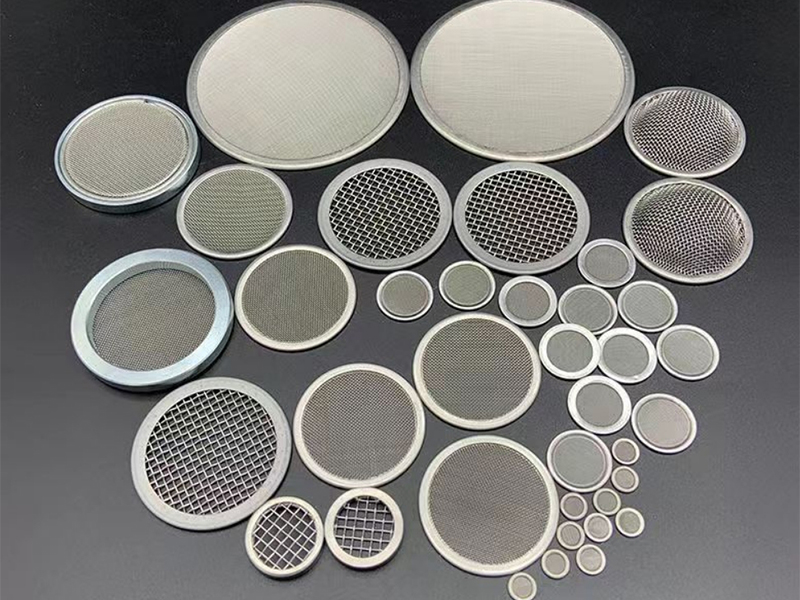

Disc Filter elements

Fine woven or sintered mesh discs for liquid and gas purification.

Learn More

Sintered Filter Cartridge

Rigid sintered metal filters with stable flow and high durability.

Learn More

Pleated Filter Element

Extended surface pleated design for high flow and long service life.

Learn More

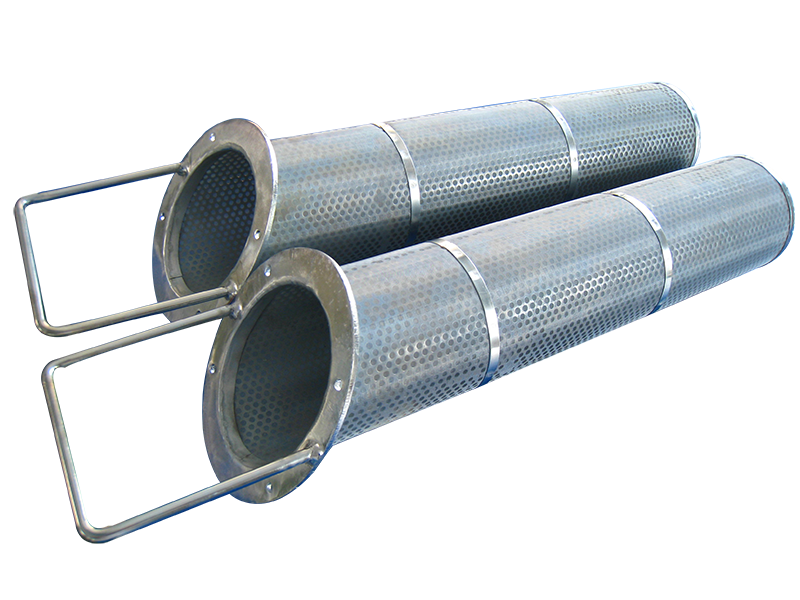

Basket Filter

Perforated or mesh-lined basket filters for coarse particle removal.

Learn More

Conical filter

Tapered cone filters for easy installation and efficient pre-filtration.

Learn More

Powder Sintered Filter

Porous sintered tubes for precise filtration and uniform air/liquid flow.

Learn More

Start Your Project with Maidong Wire Mesh Filters

We provide reliable stainless steel filtration solutions for your industry.

Contact us for OEM designs, custom specifications, and free consultation within 12 hours.

📧 Email: sales@md-wiremesh.com

📱 WhatsApp: +86-15132829996

🌐 Website: www.mdwiremesh.com

🔗more info : linktr.ee/zcc5886